If you notice your generator running a bit rough, or not running at all, one of the first things that everyone checks are the spark plug and the air filter.

Once you open the clasps and move back the cover, you see that your oil filter is no longer the white cotton-like material that it once was and is now caked with dark engine oil.

I’m going to cover the top 5 reasons why you might be finding oil in your air filter and what you can do about them. All of them can be easily remedied except for one.

As a general rule, a generator will have oil in the air filter if the oil level in the crankcase is too high, the generator is being run on an uneven surface, it has been tipped while moving it, or blow-by mist from a worn engine.

If you just want a quick summary of this article, I made a video that you can check out below.

1.) Too Much Oil in the Crankcase

Having too much oil in the crankcase is by far the most common reason for oil being in your generator’s air filter.

How it Happens:

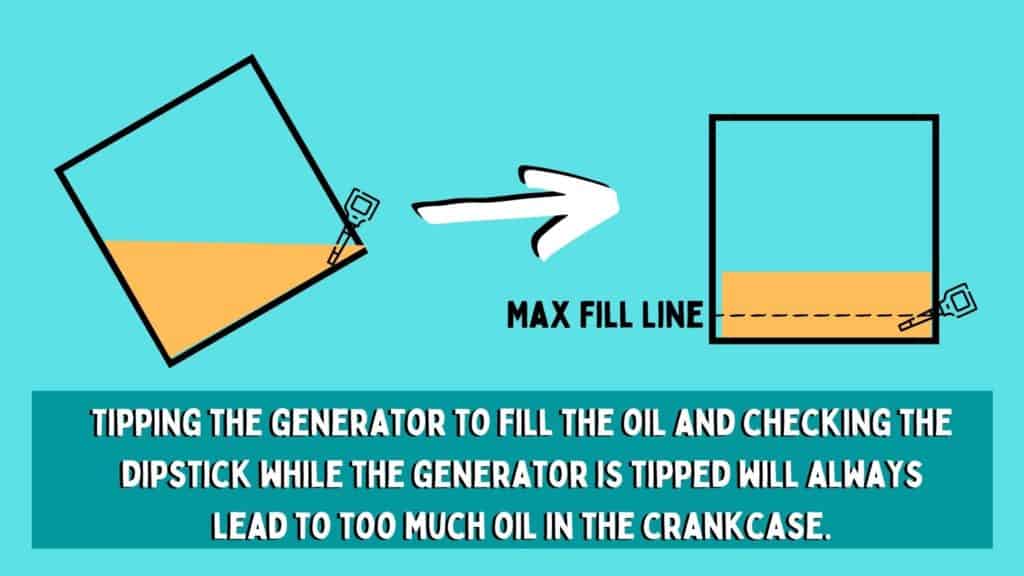

Often times it is difficult or downright impossible to pour oil directly from an oil bottle into the fill hole after an oil change. The dipstick and fill hole are usually recessed slightly and you can only pour into the hole if you put some blocks under one side of the generator and tip the fill hole towards you.

Unfortunately, this will always result in too much oil being added if you also check the level on the dipstick while the generator is tilted.

The best way to add oil to your generator is to get a funnel with a long neck that can reach your generator from where you’re trying to pour the oil.

Always check the generator’s engine oil when the generator is on a flat surface. If the dip stick reads “full” when the generator is tilted up towards you, then it will almost always overflow out of the generator if you check it on a level surface.

Why it Happens:

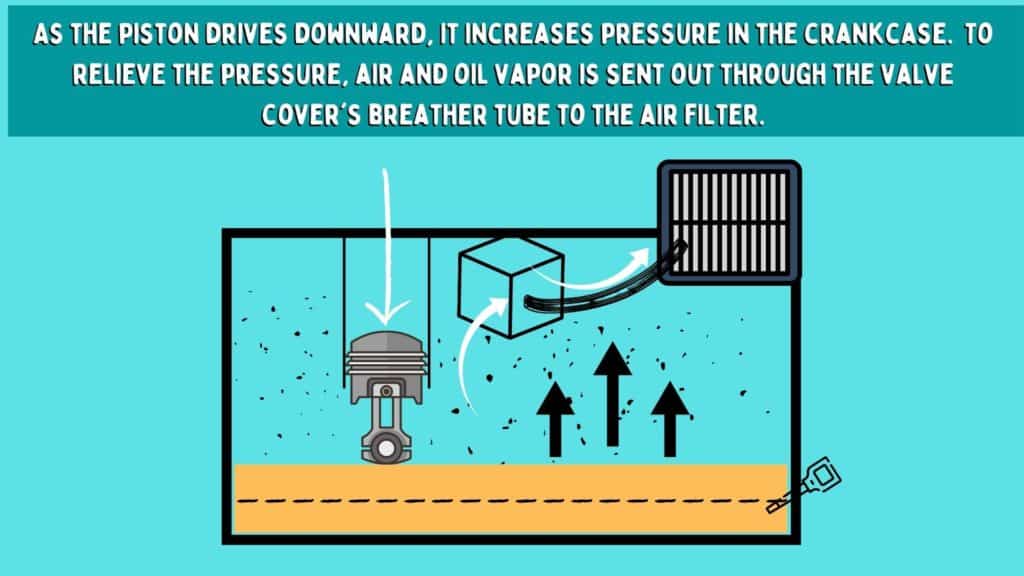

When there is too much oil in the crankcase, then excess pressures will be created in the crankcase every time the crankshaft spins and the piston descends downward.

Think of a cup with water that has a max fill line that is 1/4″ below the rim. If you stick your entire finger in the water the water will rise to the brim but won’t overflow.

If you fill the glass to the brim and do the same thing (your finger is the descending piston), then water will inevitably overflow until it has equalized itself.

The same concept happens inside your engine, but at a much faster and hotter state.

Your generator will run at 3,600 RPMs. That’s fast. That piston is driving downward multiple times per second.

The heat inside is also 200 degrees Fahrenheit (plus or minus). This means that there is liquid oil in the bottom of the crankcase and an a hot mist of oil floating around in the air as well as the heat increases, the pressures increase, and oil is splashed up into the valve cover to keep the valves lubricated.

The excess oil mist will be sloshed up to the valve cover and travel out a one way check valve and through the rubber breather tube that runs to the air filter to relieve the pressure and equalize itself.

How to Fix:

If your engine oil is too high after checking it on a level surface, simply use a wrench to open the drain plug for a few seconds to drain some out, tighten the plug, and check the level again until the desired level is reached.

2.) Uneven Surface When Running

Similar to the situation above, an uneven surface can cause problems with where and how your engine oil flows.

Most gentle angles won’t be a problem, but if things are just right you can cause an excess amount of oil to be slung up into the valve cover and it can then work its way through the breather tube and into the air filter.

How to Fix:

Operate the generator on a level surface.

3.) Tipping the Generator While Moving It

Following the principle as stated above, if you excessively tilt your generator while moving it so that the valve cover, breather tube, and air filter go towards the ground, then oil can run up and out.

How to Fix:

Build a platform with castor wheels on the bottom, order a wheel kit that will fit your generator, or have a second person help you transport it if it is too awkward to do alone.

4.) Blowby from a Worn Engine

You could have a generator that has the correct amount of oil and is operating on a level surface, but it can still have oil getting to the air filter.

This will typically happen with generator engines that have been used a lot.

Over time, oil will prevent engine breakdown but eventually all engines will develop looser tolerances.

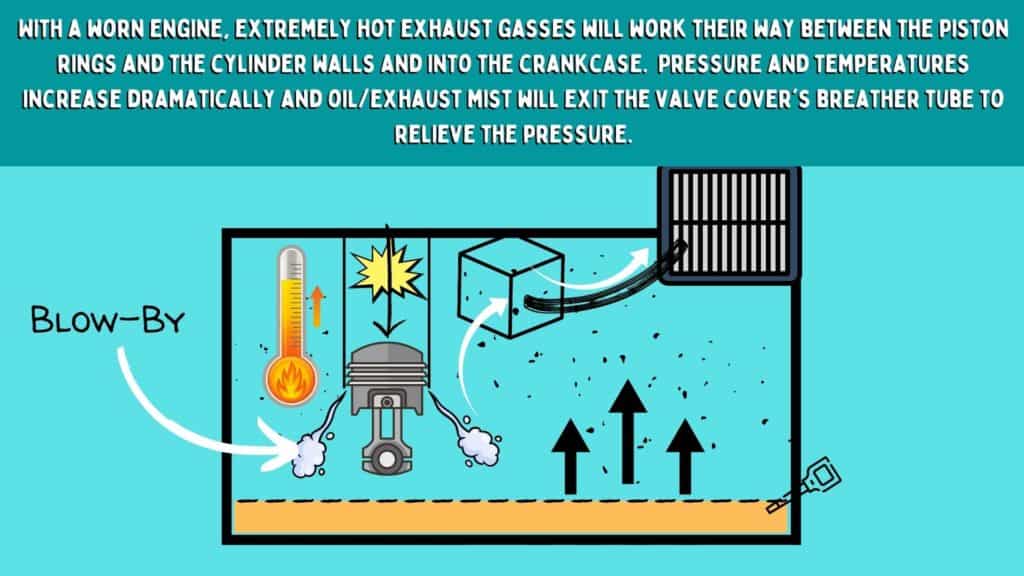

If you have any scratches on the cylinder walls or have piston rings that are no longer creating a perfect seal, you will experience what is called engine “blow-by”.

What this means is that every time your air and gas mixture combusts in the chamber, a portion of that very hot gas will be able to work its way between the piston rings and the cylinder wall and down into your crankcase.

This will increase pressures and temperatures in your crankcase and force an oil mist out of the breather tube and into your air filter.

How to Fix:

To truly fix this problem, you will either need to buy a new generator or seriously repair your current one by replacing piston rings and praying that it’s not the cylinder walls that are scored or damaged.

You can, however, easily diagnose if this is your problem by first making sure that your oil levels are correct and that you’re operating on a level surface. Let the generator run for 15-30 minutes and then shut it off.

Immediately unscrew the dipstick and watch the fill hole. If you have blow-by, you should be seeing exhaust smoke coming out of the fill hole. That exhaust can only get in there if the combustible gas is able to get between the piston rings and the cylinder wall.

5.) The Foam Pre-Filter was Oiled by a Previous Owner

This one isn’t really a problem as much as it is a misunderstanding.

Some generators will have an actual cloth-like air filter and they will have a foam pre-filter on top. It is usually recommended that this foam filter be lightly oiled (with clean oil) prior to running the generator.

The thought behind this is that dirt and dust in the air will stick to the oil in the pre-filter as air is drawn in and it will increase the lifespan of the cloth filter.

You can simply was the pre-filter with soap and water, let it dry, re-oil it, and install it.

How to Fix:

The pre-filter should be lightly oiled. It should not be dripping with oil by any means. After it is lightly oiled, you should wring it out to ensure that a bare minimum of oil is still on the foam.