It’s annoying right?

Every time you go to check the oil in your portable generator (or most small engines) you find that it needs to be topped off again. Worse would be that you don’t even see the oil level on the dipstick at all! Maybe the generator is blowing out white smoke too with the exhaust!

A generator that is burning oil isn’t something to just shrug off. It indicates an underlying problem that should be addressed so that it doesn’t turn into an even larger problem.

A portable generator will burn oil if the crankcase was overfilled with oil, it has the incorrect oil, the air filter is clogged, the piston rings or cylinder wall are scored or damaged, a head gasket is blown, a valve stem seal is bad, or a crankcase vent tube is clogged.

Before you dive into the reasons for a generator actually burning up the oil in the combustion chamber, first verify that the generator isn’t leaking oil. Make sure the drain plugs are properly secured, and feel around the valve cover and where the head connects with the engine block (head gasket) to see if a gasket is leaking.

With that being said, let’s dive into the top reasons why your generator might be burning oil!

Reasons Your Generator is Burning Oil at a Glance:

| Difficulty Level | Cause | Reason | Fix |

|---|---|---|---|

| Easy | Too Much Oil Added to Crankcase | Greater internal pressures will cause Excess oil in crankcase to seep between piston and cylinder walls, by the piston rings until it enters the combustion chamber | Drain out excess oil |

| Easy | Wrong Oil Weight | An oil with too little viscocity in the wrong season may seep by the piston rings from the crankcase to the combustion chamber since the oil will be thinner until the engine warms up | Drain out oil and refill to proper amount with correct weight oil for generator and the season (consult user manual) |

| Easy | Clogged Air Filter | Creates a greater vacuum effect in the combustion chamber when air can't be supplied. Combustion chamber will suck up oil from the crankcase to increase the pressure (fill the vacuum) | Replace air filter |

| Easy/Moderate | Clogged Crankcase Vent Tube | WIth the vent clogged (frozen condensation, for example) the crankcase pressure will build to levels above what's tolerable. Oil will either leak out gaskets to the ouside of the engine or be forced passed the piston rings into the combustion chamber. | Clear tube that usually runs from the valve cover to the air filter assembly. You may need to remove the valve cover to |

| Moderate | Blown Head Gasket | Gasket divider between combustion chamber and push rod passage is blown. Each time the piston goes down it will suck crankcase oil through that ruptured gasket like a vacuum. If smoke is coming from dipstick after running for while, this is a very good indicator that this is your problem. | Remove head, clean off carbon deposits, and replace head gasket (or take to small engine repair) |

| Moderate/Advanced | Valve seals | Oil that lubricates the intake and exhaust valves on an OHV engine can seep down into the combustion chamber if the rubber seals around the valve stems becomes damaged | Remove head and valve cover. Remove valve springs to allow the removal of the valves and access to the valve stem seals. Small engine repair shop may be needed. |

| Moderate/Advanced | Scored or Damaged Cylinder | Carbon buildup breaks off and gets trapped between piston and cylinder wall resulting in a groove getting cut which renders the piston rings useless as oil leaks right by the groove and into the combustion chamber | Take to small engine repair shop or remove the head from the engine, disconnect spark plug, and turn flywheel until piston goes down. Visually inspect and run finger along the cylinder wall to verify the problem. If damaged, it's likely more cost effective to scrap the unit and purchase a new one than to fix it. |

| Advanced | Worn, Damaged, Misaligned Piston Rings | Oil is allowed to seep by the rings and into the combustion chamber from the crankcase | Complete engine disassembly is needed to diagnose and confirm. Easiest to take to small engine repair shop. |

| Advanced (or Ruling out all Other possibilities) | Looser tolerances due to use over the lifetime of the unit | Wear and tear over the years of use creates a wider gap between the piston and the cylinder walls which allows oil to seep passed and into the combustion chamber from the crankcase | If all other options are ruled out, this may be the case. A heavier oil viscosity (thicker) may help since it won't flow by the piston rings as easily |

What is Essentially Happening for Your Generator’s Engine to be Burning Oil?

To put it simply, there is either a mechanical failure in your engines ability to seal out the engine oil from climbing up the cylinder walls and into the combustion chamber, or there is a greater vacuum than normal being created in the combustion chamber and it is pulling up oil from the crankcase regardless of anything else.

With that being said, let’s quickly touch on some of the main reasons and what to do about it.

Too Much Oil Added to Crankcase

If you bought your generator used, or filled it while lifting the generator up on a 45 degree angle, then you might be burning oil – in the truest sense of the word – simply because the crankcase is over capacity.

This won’t result in you checking your dipstick and seeing that it’s a bit low and asking yourself why, rather, this will result in your generator blowing out copious amounts of white smoke so that mosquitoes from 100 yards away will have no interest in bothering you.

If you were to pull the dipstick to check the oil level, the oil would likely spill out of the dipstick housing and all over the ground until it leveled itself out within the generator. Typically, most generators require the oil level to be right at the top of the threads where the dipstick screws in.

So if you buy your generator used, always check the oil level before starting it, and if you are changing the oil yourself, use a funnel to help get the oil in the crankcase instead of propping the generator up on a 45 degree angle for easier filling.

To fix this problem, open the oil drain plug and allow oil to flow out until you reach the desired level. You will have to cap it off periodically to check.

Wrong Oil Weight

If you use the wrong weight of oil, especially one with a low viscosity for what the manufacturer recommends (or the season and temperatures call for), then you may find your oil levels dropping as the engine runs.

This is due to the oil gliding up along the cylinder wall and being thin enough to really work its way between the piston and the cylinder walls, and also work its way up through the small single gaps in each of the three piston rings. Eventually, the oil will be on top of the piston and will burn up during the combustion process with the fuel and air mixture from the carburetor.

Depending on how much makes it up with each stroke will determine how much of a noticeable white smoke that you will see coming from the exhaust.

If you bought your generator used, or if you’ve never changed your oil yourself on your particular model, it’s best to consult with your operator manual and most can easily be found online in PDF format.

I typically run synthetic 5W-30 oil in my generators but I’m in Michigan, so your climate may call for something else.

Clogged Air Filter

This is by far the easiest to check. Generally, on one of the corners of the engine side of your generator is the air filter assembly. The cover is usually held in place by 2 clamps on modern generators or with two thin bolts on older ones.

Simply release or remove whatever is holding the cover in place and check the air filter. They start out white, so use that as your reference with how dirty they are. If your generator is caked with oil residue and dirt, then it will be causing the generator to burn oil.

This happens because each time the piston drops down during the power stroke or the intake stroke, the cavity in the combustion chamber expands in size and this decreases the pressure (which creates a vacuum). This would normally result in the vacuum being filled by air flowing through the air filter and then through the carburetor (where it picks up fuel) and then to the combustion chamber.

If the air filter is clogged and very restricted, the vacuum in the combustion chamber will suck up oil that is lubricating the cylinder walls to neutralize the pressure difference.

Once on top of the piston, the oil gets burnt off with whatever air and gas the combustion chamber could get from the intake side (the air filter and carburetor).

To fix, simply replace your air filter.

Clogged Crankcase Vent Tube

If you locate where your valve cover is (it is labeled “OHV” on overhead valve engines), you’ll see that there is a thick black hose that leads to the air filter assembly.

This is the breather tube or vent tube for the pressures that build up in the crankcase. If there is any blowby (exhaust from the combustion process that gets passed the piston rings and into the crankcase with the oil, or simply excess pressure from heat build up, the vent tube allows the gasses to recycle back into the air filter assembly and back into the carburetor for reuse in the combustion process.

If this breather tube gets obstructed in any way (often by frozen condensation in cold weather), it will not allow the pressures to bleed out of the crankcase. At some point, the oil and pressure will escape by the path of least resistance. This might be through a gasket to the exterior of the generator (often your overhead valve cover), or the pressure might go right back up the cylinder wall while carrying oil to the top of the piston to be burned in the combustion chamber.

If you get the oil hotter than its supposed to be and combine it with the hot exhaust from the blowby, it will break down the viscosity of the oil and it will become “watered down” (so to speak) and more readily slide by your piston rings to be burned up.

Detach this tube and remove your valve cover to make sure all of obstructions are cleared out.

Blown Head Gasket

A blown head gasket can blow exhaust or oil to the outside of the generator, or you can have a blown head gasket with one of the internal dividers that separate the combustion chamber from the oil galleries and valve pushrods (which are lubricated by oil from the crankcase).

What will really cause you to burn oil is if your internal divider blows out between the combustion chamber and any other pathway that carries oil from the crankcase.

Again, as the piston drops down, it will create a vacuum effect and will pull in air (or whatever it can) to fill the void before it rises back up again. If the gasket between this combustion chamber has access to a port with engine oil, then it will suck oil from between the blown gasket and burn it up during the combustion process.

The other effect is that the hot exhaust will be pushed through that same gasket and into the crankcase each time the piston rises up. So, you’re really making a mess of things.

If your generator is blowing out white smoke and you pull your dipstick after it’s been running and there is hot and smokey exhaust coming from your oil, then you very likely have a blown head gasket.

The fix is going to depend on exactly which make and model and engine type that you have, but you’ll need to remove the head. Once that’s done, scrape off the old gasket and use a wire brush on a Dremel to clear off any carbon buildup. Make sure you change your oil from all of the exhaust mixing with it or your oil will turn to sludge.

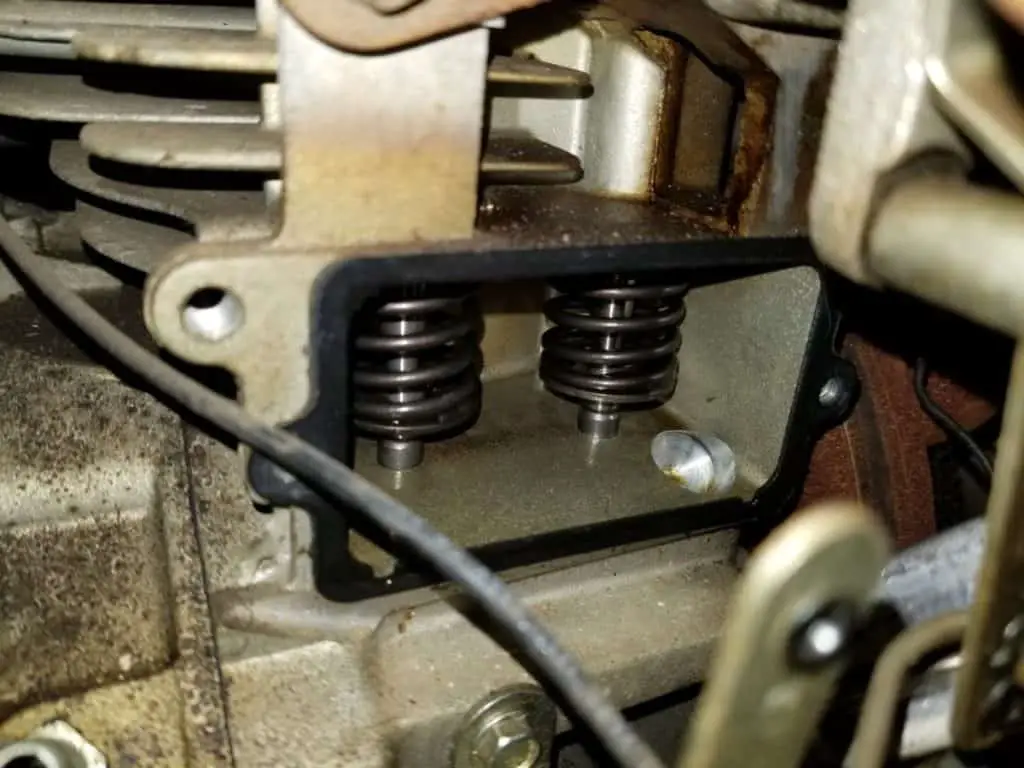

Valve Seals

Your generator may or may not have rubber valve stem seals. On my latest refurbishment project, the generator I’m working on (flat top engine) only had a valve stem seal on the intake valve, if I remember correctly.

Anyway, these rubber valve stem seals basically hug the shaft (or stem) of the valve and keep oil from passing by a certain point. If the seal rots away or is damaged, then oil is allowed to slip by and on OHV engines the oil will drip into the combustion chamber as the valves open up above it.

Once the oil drips in, it will burn off with the gas and air from the carburetor.

I’m just a hobbyist who has been doing small engine refurbishments for 5 years and not an expert, but I believe this really only affects OHV engines. At least, those are the only ones I’ve seen a problem with.

Depending on the engine type you’ll need to remove the valve cover and maybe the head as well to access everything that you’ll need.

Scored or Damaged Cylinder

This one also involves removing the engine head to confirm a diagnosis.

If you have and engine that is running rich (more gas than air in relation to the proper air to fuel ratio), then it will experience incomplete combustion and will generally exhaust black smoke to release the improperly combusted carbon. Some of this carbon sticks to the walls and top of the piston in the combustion chamber.

After a while, the carbon will build up and eventually break off and will be a hard piece of debris. This will get wedged between the piston and the cylinder wall and as the piston moves up and down it will cut a groove in the cylinder wall.

After this, the oil from the crankcase is free to flow right up the groove and into the combustion chamber to be burnt off. The piston rings will be rendered ineffectual after this occurs.

To confirm this is the case, remove the engine head and with the spark plug removed, turn the flywheel clockwise until the piston drops down. Visually inspect and run your finger along the walls of the cylinder. If you have cuts and grooves in it, you will continue to burn oil.

To fix, you would have to replace the engine itself or bore out the cylinder and fit with a new piston. Either way, you’re looking at a ton of money and by the time this happens your generator has probably depreciated in value to where the cost to repair would exceed the resale value of your generator. It’s best to probably move on to a new purchase.

Worn, Damaged, Misaligned Piston Rings

To properly confirm this yourself, you would have to fully disassemble your engine and remove the head. It won’t be fun unless you’re into that kind of thing.

If the rings are compromised or misaligned they will allow oil to glide passed them and into the combustion chamber to be burned off.

If you replaced piston rings at any point on your generator, make sure that when you installed them that the gap on each ring was staggered 120 degrees from each other and not aligned right on top of each other. If the gaps are all lined up, the oil will flow right through them with limited resistance.

A small engine repair shop should be able to do a pressure test on your combustion chamber and diagnose if your piston rings are bad or if you have a blown head gasket (by listening to where compressed air exits the engine if there is indeed a leak).

I recommend having this serviced by a professional if you don’t have the experience or the confidence to not screw things up upon full disassembly and reassembly. However, I would try to rule out the other possibilities (especially the easy ones) before you resort to taking it in to save yourself some money.

Looser Tolerances Due to Use Over the Lifetime of the Unit

Let’s face it, every engine has a finite lifespan. As your engine ages and wears out, the tolerances between the piston and the cylinder wall might open up ever so slightly. Once that happens, oil will be able to flow passed the piston rings that much easier — even if everything is still working properly.

There’s not much you can do to turn back time. You might get away with running a heavier weight oil with a higher viscosity for a little bit. This will effectively make the oil thicker and less prone to slipping by the piston rings.

However, you’ll want to be careful not to run an oil through it that won’t properly lubricate and cool your engine, or you can end up with a seized engine. Then, instead of an engine with slightly decreased performance and that needs to be topped off with oil, you’ll have one that won’t run and has warped internally from overheating.

Let me know how it goes!

If I’m missing anything or if you’ve got another common reason why an engine might be burning oil, let me know and I’d love to update this list. I enjoy buying very cheap generators (or getting them for free) that don’t run and flipping them after I’ve fixed them up, so these are the reasons I can think of from my experience. I know there’s still a lot to learn. Good luck fixing your generator!

contact.homebatterybank@gmail.com