You definitely know something is wrong with your generator when you hear loud pops and maybe even flames or smoke coming from your exhaust or your carburetor. Most people when they experience any of these symptoms will simply say that they are experiencing “backfire”.

There’s actually a difference between true “backfire”, which is when your you hear pops or see flames from the carburetor, and then there’s “afterfire” which is when your exhaust makes a pop or flame through the exhaust itself.

Generators backfire from the carburetor due to a lean air-fuel mix, a timing issue (early combustion), or a stuck intake valve. Afterfire occurs through the generator’s exhaust and is due to a lean or rich air-fuel mix, a timing issue (late combustion), or a stuck exhaust valve.

In this article I’m going to talk about what causes backfire and afterfire in a generator, if they can damage your engine, and how to fix them.

Let’s jump right in!

What Causes Backfire Through the Carburetor

Backfire through the carburetor can be categorized into one of 3 broad issues (or a combination of them):

- Lean Air-Fuel Mixture

- Timing Issues (Sparkplug/Ignition Coil, etc.)

- Intake Valve Stuck Open (Myriad of Reasons)

Lean Fuel-to-Air Conditions

Running an engine with a lean fuel-to-air ratio causes a slow combustion in the combustion chamber. When this happens and the piston is on its power stroke, the combustion process is occurring but it’s well behind the time it would have taken if the proper air to fuel mixture ratio was achieved.

So at the end of the power stroke when everything should have already combusted, the combustion process is still occurring as the piston now cycles back up during the exhaust stroke to expel the burnt combustion out through the exhaust.

However, in this case, there is still a flame as the combustion process is still occurring and still some fuel that hasn’t been combusted. It wouldn’t be so bad if only the exhaust valve was opened during the exhaust stroke, which it primarily is at first. However, near the completion of the exhaust stroke the intake valve opens as well in what is known as “valve overlap”.

When the intake valve opens, a new batch of fuel and air is being sucked into the combustion chamber like a vacuum and the flame that is still occurring due to the slow combustion can instantly ignite with the new air-fuel mixture and travel back up through the carburetor. The result will be a pop, a flame, or a flame that leads to a fire.

Reasons that your engine might be running lean might have to do with your jets being restricted, a vacuum leak occurring in any gaskets that are damaged between the air filter and the combustion chamber, your settings on your carburetor (like the screws being improperly adjusted), or you might have bad fuel.

I have an entire article and video here if you need help with removing, cleaning, and adjusting your generator’s carburetor.

Timing issue

When it comes to a timing issue with backfire through the carburetor, an early spark is definitely the problem in this case. Ideally, during the intake stroke, your piston descends down and pulls in an air-fuel mixture and then the valve is supposed to shut as the piston starts its path back up for the compression stroke.

If the timing is off however and the spark from the spark plug ignites the mixture before the valve has shut from the intake side then compressing air-fuel mix will ignite and blow straight back out throuh the carburetor. it will blow the combusting air fuel mix right back out through the carburetor.

Reasons your timing might be off could include a flywheel key being sheared, your Ignition coil going bad, or a faulty spark plug.

Stuck Intake Valve

The intake valve which opens and closes and allows new air fuel mix from your carburetor into the combustion chamber can definitely cause backfire through the carburetor if it is in the open position when it shouldn’t be.

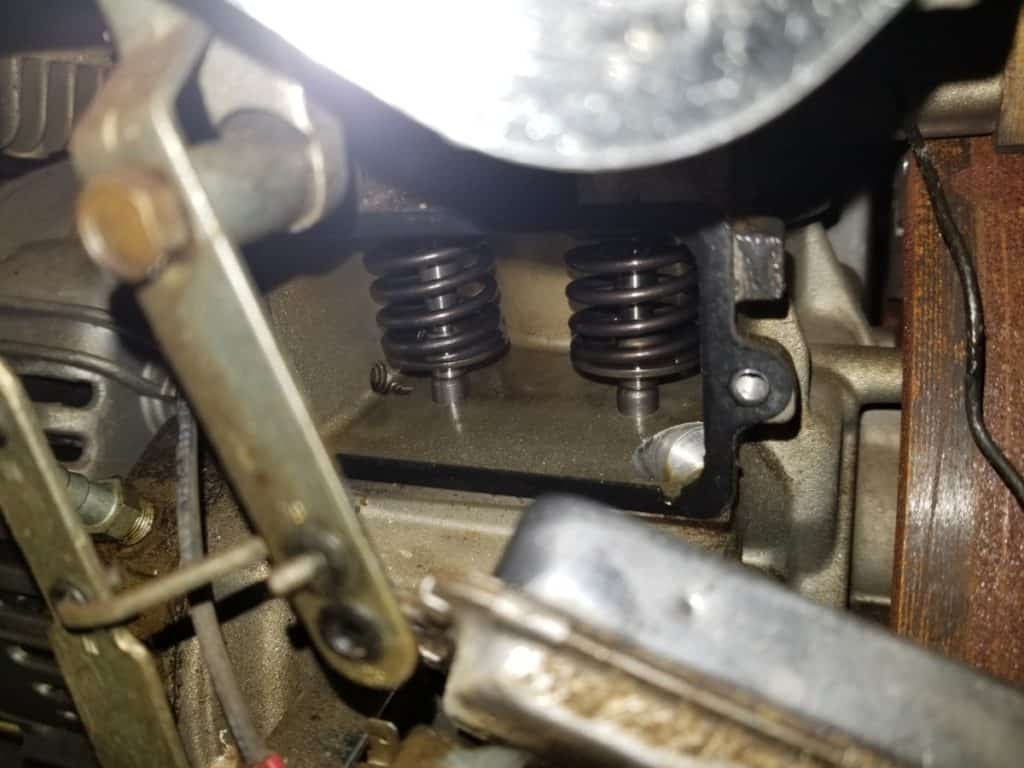

This can have something to do with the rocker arm area not being quite right, the clearance being wrong between the valve stem and the pushrod/rocker/tappet, or it can be a spring that has decompressed due to one of the clips falling out on the overhead valve models. It can also occur if your valve has simply rusted up.

In any of these issues, if the intake valve is open or cracked when it shouldn’t be, the exhaust or combusting air-fuel mix is necessarily is going to blow back through the carburetor. It may blow back through the exhaust as well, but definitely through the carburetor if the valve is open in any way.

To find out if you have an issue with your valves you’re going to have to remove the valve cover at the minimum to check the rocker arm/tappet area and make sure that all the springs are compressed, the clearances are what they should be, and that nothing is bent or damaged.

Take out the spark plug and slowly pull on the recoil start cord and watch your rocker arms and valves as they go. Check and see if any of the valves are not moving.

You may have to remove the head to the combustion chamber to diagnose any further problems such as the face of the valve being damaged, or having too much carbon build-up between the face and the seat. This would prevent it from closing properly and allowing exhaust gasses back through your carburetor.

What Causes Afterfire Through the Exhaust

Afterfire, the loud booms and possible flames that you see coming out of your exhaust, can happen for one of 4 broad issues.

- Lean Air-Fuel Mix

- Rich Air-Fuel Mix

- Timing Issue (Delayed Combustion)

- Exhaust Valve Stuck Open

Afterfire from a Lean Air-Fuel Mix

Like with backfire an afterfire can also occur due to a lean running engine. Because a lean mixture burns slowly, it is still combusting when exhausted. So, depending on how bad that lean mixture is, you may get some that goes out through the carburetor which creates a backfire, but the majority will go out of the exhaust in and after fire since it is happening during the exhaust stroke.

This is definitely where you could see flames coming out as the combustion process was still underway when it was being exhausted.

Afterfire from a Rich Air-Fuel Mix

A very common cause of afterfires is also a rich air-fuel mixture entering the combustion chamber from the carburetor. If you have too much fuel in relation to the amount of air that goes into a combustion chamber, then the lack of oxygen won’t be enough to ignite all of the fuel that’s in there.

As your piston goes through the power stroke and a portion of the fuel is not burned due to a lack of oxygen, then that unburnt fuel will be pushed out into the hot exhaust during the exhaust stroke. Once the unburnt fuel mixes with air and is in a high heat environment like the exhaust manifold, then it can spontaneously combust and make a very loud popping or banging sound. The intensity of that will depend on how much unburnt fuel there was as it entered the exhaust manifold.

Timing Issues (Delayed Combustion)

We mentioned before that a timing issue can cause a backfire through the carburetor — especially if it was an early spark in the combustion process that occurred before the intake valve closed. The same thing can happen on the other end of the spectrum if the spark occurs too late.

If when the piston is compressing the air-fuel mix and the spark should go off but is delayed and decides to spark as the piston is now descending on its own due to momentum, the combustion process will now be occurring late and will continue on through to the exhaust phase and the piston will drive out the still combusting air-fuel mix out into the exhaust manifold.

When this happens you’ll can see a flame or just hear loud bangs or pops.

Timing issues can occur due to a flywheel key being sheared which will effect when the signal is given to the ignition coil to fire the spark plug. Timing issued can also be as simple as the spark plug itself being bad, or the Ignition coil being bad.

Exhaust Valve Stuck Open

Finally, just like with backfire, a valve issue can have much to do with afterfire as well.

If you have too much carbon build-up on the face or seat of the valve, then it will not allow a proper seal and you can have the piston push out the air-fuel mix into the hot exhaust manifold during the compression cycle. Your valve could be damaged in some way, or the clearance could be wrong.

Just like with diagnosing the backfire issue you’re going to have to remove the valve cover to check the rocker arm areas, the clearances, and make sure all of the springs are compressed and that everything is where it should be. You may have to remove the head of the combustion chamber to diagnose any further problems.

How Do You Fix a Backfire?

From my experience, to fix a backfire you need to first classify the backfire into whether or not it’s a continuous thing, or if it’s happening at a certain time like upon start-up, shut-off, or when the engine is dropping from a high RPM.

If it is a constant thing it’s more likely a problem with your air-fuel mix, which would more than likely be a fuel or carburetor issue, or a bad spark from a faulty spark plug.

A proper cleaning of your carburetor can go a long way in fixing a lot of issues with small engines and in my experience at least 80% of all problems stem from the carburetor or involve it in some way. I have a full article with photos and a video that guides you through step-by-step how to properly clean a generators carburetor if you’d like to check that out here.

If your backfire occurs during start-up and the engine won’t start properly or stay running, I would focus on a valve issue. It could have anything to do with the clearance not being correct between the valve stem and the pushrods/tappets/rockers, it could be a spring that has come decompressed (especially on an OHV engine), a bent rocker arm, carbon buildup between the valve face and the seat so that a proper seal isn’t created, or more.

There’s a whole myriad of issues that could happen from the valve face in the combustion chamber down to where the valve is being pushed on by the rockers/tappets/pushrods.

I like to buy generators at a great price from people who can’t get them to run and then I flip them for a profit as a side-hustle. My last generator that I worked on wouldn’t start, but it would afterfire through the exhaust. When I removed the head of the combustion chamber, I could see that the exhaust valve was able to open and close, but in the closed position it was still open by about 1/8″ or so.

In that situation, the engine could never fully compress the air-fuel mix, and anything that did happen to combust was half-heartedly shot out through the exhaust while combusting. It was a flat-top engine, so I just needed to grind down the valve stem a very tiny amount to get it to the correct clearance between it and the tappet/push rods.

If your backfire occurs when your engine is abruptly turned off after running at a high RPM, then the backfire is generally caused by the piston still completing some cycles without a spark (remember, the generator runs at 3,600 RMPs). If the piston cycles, then it’s still sucking air and gas into the combustion chamber. If hot enough, that air-fuel mix can spontaneously combust in the chamber or in the hot exhaust manifold.

To prevent backfire when shutting down your generator, be sure to unplug everything running off of it and let the generator idle for a minute or so before turning it off.

If you experience backfire when the RPM’s drop dramatically in an instant, then it is more than likely just the engine having a high amount of fuel since it was just running fast to now having excess fuel because it is now running slower and that excess fuel combusts spontaneously in the exhaust manifold.

Can a Backfire Damage a Generator’s Engine?

When it comes to whether or not backfire or afterfire can damage your engine, there’s a few things to consider.

Typically, if you’re experiencing afterfire, which is when the popping sound comes from your exhaust, it’s not that big of a deal for immediate damage if the popping sounds are low and not violent.

Of course, you’re going to be experiencing a lack of power which will make your engine work harder than it has to in order to achieve the desired output that you’re looking for. So in this sense, yes, it can damage or wear down your engine in the long-term.

If the popping is loud and violent to where would scare anybody within a 30′ radius then, yes, there is always a chance that and afterfire could damage your exhaust manifold or the exhaust itself.

When it comes to true backfire, which is where the popping sound and the exhaust is expelled through the carburetor, then that is more worrisome to me than an afterfire.

The reason it is more worrisome is the increased risk of fire because you actually have gasoline stored in the carburetor ready for combustion, whereas afterfire is simply the end of the road for the combustion process and there is nothing left to burn.

I would not let an engine continue running if I were experiencing true backfire through the carburetor, whereas I might tolerate a mild case of after fire through the exhaust if I didn’t have the time or tools to fix it. All it takes is delayed combustion to produce a flame that passes through your carburetor from the combustion chamber to ignite the gasoline in your carburetor and create a fire.