I know you’re probably in a hurry to get back out and finish up the lawn, so let’s skip the usual obligatory opening paragraphs.

Your push mower is surging or revving up and down and you want to fix it, right? Let’s get started.

I’ve been repairing small engines over the last 7 years and I’m going to share the top 4 reasons I’ve found for a surging push mower and how to fix it.

As a general rule, a push mower’s surging and revving up and down is due to an inconsistent ratio of fuel to air during combustion and is caused by a restricted pilot or main jet on the carburetor, a dirty air filter, stale gasoline, or a throttle linkage spring (return spring) that is missing, broken, or disconnected.

Below is a quick reference table with each of the top 4 reasons, why it’s causing the problem, and how to fix it. A detailed explanation for each is given throughout the rest of the article, along with a quick video I made to give you a better visual explanation.

| Cause for Surging/Revving Up and Down | Why It’s Surging | How to Fix |

|---|---|---|

| Pilot Jet or the Main Jet is Restricted | Not enough gasoline can get to the engine during operation, likely caused by stale fuel sitting in the carburetor and turning to a hard or tacky varnish ***A clogged pilot jet is the most common reason in this article for surging or revving up and down*** | Drain out all stale fuel in the tank and carburetor Clean out pilot jet on side of carburetor first and test. If that doesn’t fix it, remove air filter assembly and carburetor to clean out the bowl, main jet, and the emulsion tube |

| Dirty Air Filter | Choking the engine from getting enough air for combustion, engine will generally sound more bogged down with its surging and may be a little smokey than have a true high and low surge pattern. | Remove air filter, check for extreme dirt, check to see if it’s wet with oil or gasoline. Run the mower without the air filter for a moment to see if the problem is resolved Replace if needed |

| Stale Gasoline | Gasoline that is 3+ months old and hasn’t been treated with a fuel stabilizer is stale and will have reduced combustion properties in the engine, causing inconsistent engine performance | Drain all fuel from the tank, fuel lines, and the carburetor bowl. Refill with fresh fuel that has been treated. |

| Broken, Missing, or Disconnected Throttle Linkage Spring | A spring that is missing or not connected will not absorb the changes in engine speeds and smooth them out. Often happens when you mow under a bush or low hanging branch and the spring is hit by something. Engine will sound erratic and will usually be a faster surging | Reconnect the spring if disconnected. If missing, replace it. If broken (usually right at the hooked end), make a new hook on the end with a pair of needle-nose pliers and stretch out one of the coils just a little to slightly lengthen the spring and reconnect. Spring should be taut. |

Mower Surging from a Clogged Pilot or Main Jet in Carburetor

By far, in my experience, the most common reason for a surging push lawn mower is a restricted pilot jet.

Don’t get tunnel vision though, as it can still be other things, but this has been the most common fix for me with the engines that I’ve worked on.

Luckily, it’s just about the easiest carburetor fix that you can do as well.

If you have a lawn mower with a simple carburetor (has the metal bowl on the bottom) then you can finish this task in under 2 minutes.

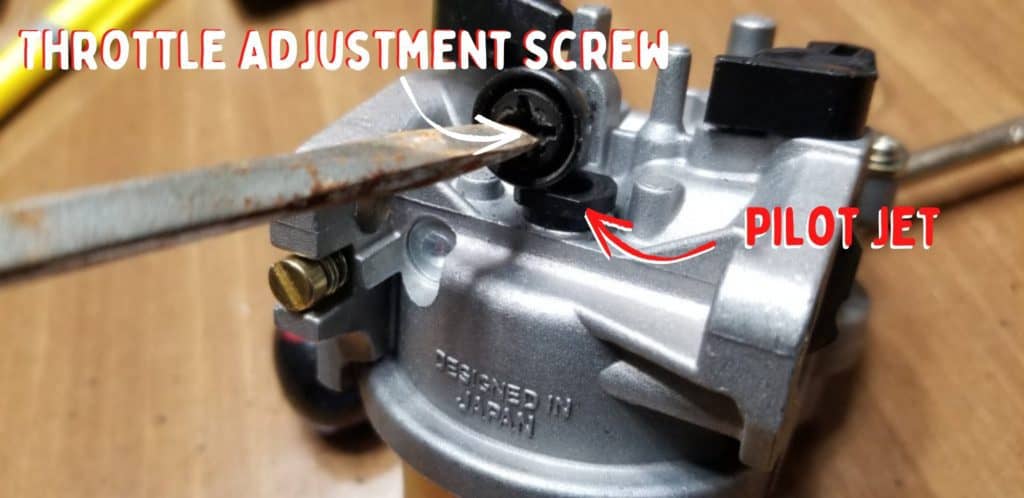

Simply locate the carburetor and take a screwdriver and screw in the throttle adjustment screw — but count the number of full turns that it takes to screw it in all the way.

Write that number down and then remove the screw.

Below that screw is a plastic piece. Take a pair of needle nose pliers, put the tips on each side of that plastic piece and gently pry it up.

You are now holding the pilot jet.

There is a larger lateral hole that runs through the side of it for air. On the bottom tip is a small hole and this is what needs to be cleaned.

Burn off the end of a twist tie to expose the wire inside. Then take the wire (cooled, not hot) and push it through that small hole. Do this several times to work out any grime or varnish that has formed from stale gasoline.

Put the jet back in, screw the throttle adjustment screw in all the way, and then back it out the number of turns that you wrote down so that the engine is back to where it was before you began.

Fire it up and see how it sounds.

Before you tear apart the whole carburetor to clean the main jet, I recommend checking the following sections first (stale gasoline, clogged air filter, compromised throttle linkage spring) since they are easiest to check and could very well be your issue.

Assuming you’ve checked the other things first, you can proceed with cleaning your carburetor and main jet.

There are two very common carburetors that you’ll come across and I’m assuming you’ll fit into one of the two categories for the following videos. These aren’t mine, but they’ll guide you through the process. It’s easier to watch this instead of me trying to explain such a visual process.

Mower Surging from Stale Gasoline

If you are trying to use gasoline from last summer and you know that you didn’t treat it with a fuel stabilizer, then I can almost guarantee that this is your problem.

Regular E10 gasoline starts to degrade in performance in as little as 30 days without a fuel stabilizer being added. It should be discarded properly after 3 months.

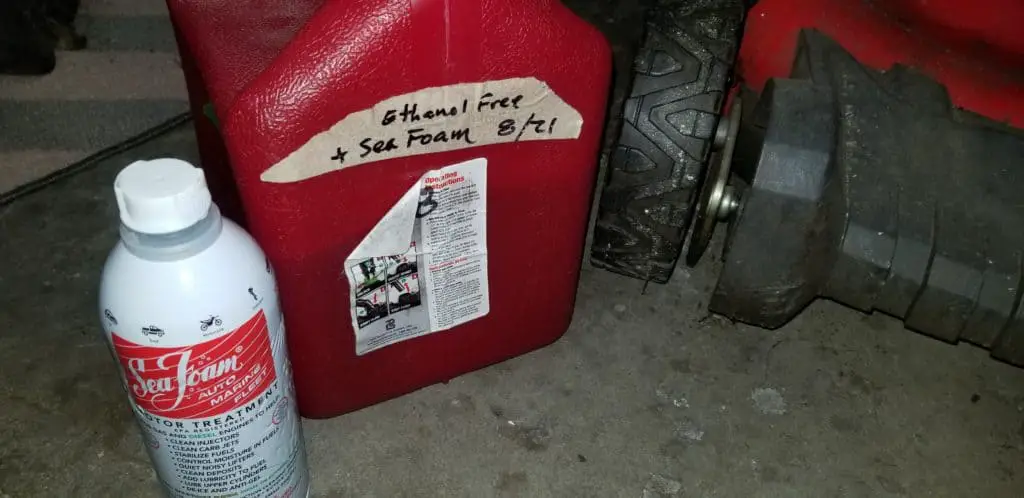

Ethanol free (marine gas) holds its integrity a bit longer, but it still starts to lose its performance after 3 months and should be discarded after 4-6 months if you didn’t use a fuel stabilizer.

Gasoline has hundreds of additives in it that, along with the gasoline itself, are degraded by oxygen. The “light ends” are the most combustible part of the fuel and if a stabilizer is not used, they evaporate first. That leaves the heavier ends which are less combustible.

As a few months go by, the gasoline starts to turn from a clear liquid into something a little more Mountain Dew looking. It will start to get a rancid smell and the aged fuel will actually turn into a varnish inside your tank, the fuel lines, and the tiny jets and passageways in your carburetor.

This hard coating builds up like plaque between your teeth. If you floss properly you can push water between your teeth. If you eat sugar all day, you will find by the end of the day that you cannot push hardly any water between your teeth until you floss again, even if there’s no actual food stuck in between your teeth.

If you have stale gasoline, then you are supplying your lawn mower with inconsistent combustion and it will be working really hard to keep running and the resulting sound can be perceived as surging or revving up and down.

To fix the stale gasoline problem, just drain the tank by disconnecting the fuel line at the carburetor and letting the stale fuel pour into a jar, or pump it out with a battery operated pump.

Be sure to drain any of the gas in the carburetor bowl too.

Once this is done, you can refill with fresh fuel and see if it is better. If it’s a little better but still running a little rough, it is best practice to clean the main jet, the pilot jet, and the emulsion tube in the carburetor. (See instructions in the first section about cleaning the carburetor)

To prevent your gas from going bad in the future, be sure to stabilize your fuel upon purchase. I recommend ethanol free gasoline (click link to see your closest gas station) and SeaFoam, which will keep your gasoline good for up to 2 full years. I’ve personally tested this claim and it the tested gasoline still ran perfectly after that time period.

Mower Surging from a Dirty Air Filter

A dirty air filter can cause surging or can simply make your lawn mower sound very bogged down and be under powered. In this situation, a clogged air filter is not allowing enough air to pass through the carburetor to mix properly with the fuel.

As a result of the engine trying to pull air that it cannot get, it will actually draw more fuel up to make up the difference in pressures.

The excess fuel to air ratio will cause the engine to combust improperly.

Symptoms of a dirty air filter include:

- Increased fuel consumption

- Smokey exhaust

- Popping from the exhaust

- Under powered

- Stalls when cutting longer or damp grass

- Surging

Luckily, this is just about the easiest thing to check.

Just undo the clasp, or unscrew the nut that holds your air filter cover on and remove the air filter. You should be able to judge if it’s dirty or not. A white filter that turns to light, or even medium gray is probably still just fine. A white filter that turns dark gray or black should be replaced.

To test if your air filter was the problem, simply remove it and start the engine again. If the engine problems are fixed, then simply replace the air filter and you’ll be back in business.

If your lawn mower’s air filter is soaked with gasoline, then you either tipped the mower over on its side incorrectly or your float needle valve in your carburetor is malfunctioning and needs to be cleaned or replaced.

Mower Surging from a Compromised Throttle Linkage Spring

Generally a surging or revving issue caused by a compromised throttle linkage is a sudden happening or something you inherit from a used mower that you got for free at a great deal.

This spring either works or it doesn’t, so there’s no slow slide into your surging problem. You might be halfway through your lawn, everything is working fine, and then your engine starts surging quickly.

This is a common problem if you mow under low hanging spruce branches, or other shrubs. If anything hits the spring it can disconnect it or break it.

Unless you got your mower for free from a neighbor who couldn’t identify the issue, you likely will still have the spring still connected to the governor arm. If the hook is still intact, just put it through the small hole beside where the throttle arm linkage joins with the top of the carburetor’s throttle lever.

If the hook is broken but the spring is 95% still intact, go ahead and make a new hook with some needle nose pliers and stretch it to the hole on the top of the carburetor’s throttle lever.

You may need to stretch one of the coils out just a little to give it a little slack.

You want the spring taut, but not so tight that it’s stretching when doing nothing.