I know exactly where you’re at right now.

Your generator starts up just fine, or maybe you just needed a quick shot or two of starter fluid in the intake to get it fired up. Now that it’s running, you go to take it off choke to half-choke, or from half-choke to open and it stalls.

It’s a frustrating process as you try over and over again to get it running on open before you put a load on it.

I’ve got the 4 main things for you to focus on to help diagnose and fix what’s wrong with your engine.

If you’re just here for the quick answer as to why your generator only runs on half-choke (or full-choke), then this is what I would tell you:

As a general rule, the reasons a generator will stall when the choke is turned off are due to stale fuel, a clogged or restricted main jet, a clogged or restricted pilot jet, a loose fitting carburetor, or damaged carburetor gaskets. When the choke is turned off, the carburetor allows more airflow into the combustion chamber. If the air-to-fuel ratio is not correct when this takes place, then stalling will occur. This can be a fuel problem or an airflow problem.

Let’s dive in and quickly go over what you need to do to get your engine running with the choke open so that you can start powering your house!

| Reason a Generator Stalls when Choke is Off | Why is Causes it to stall | How to Fix |

|---|---|---|

| Stale Fuel | Gas is less combustible and the engine will have too low of a fuel-to-air ratio for combustion when the choke is off | Turn off fuel valve, drain carburetor bowl, disconnect fuel line from carburetor and drain gas from tank |

| Clogged or Restricted Main Jet | Not enough gas can be pulled up from the carburetor bowl when the choke is turned off and the air-to-fuel ratio becomes too high for combustion. (Generally if problem occurs while running a load, but it’s worth checking before checking the pilot jet for idle issues) | Turn off fuel valve, drain and remove carburetor bowl, spray carb cleaner up through the main jet or use a small wire (twist tie) to ream it out. It is recommended to remove the main jet and emulsion tube for proper cleaning and can usually be done without removing the carburetor. |

| Clogged Pilot Jet | The pilot jet also has fuel pass through it after the main jet and if it is restricted or clogged the fuel-to-air ratio will be too low for combustion when the choke is off (Generally if problem occurs while at idle only) | Remove the throttle adjustment screw and lift out the jet, clean out the small pin-hole sized orifice at the bottom with a twist tie wire |

| Carburetor Not Tight or Gasket Damaged | If the carburetor is not tightly mounted or the gaskets on the carburetor are damaged, the engine will have too high of an air-to-fuel ratio when the choke is turned off (which allows more air) | Verify that the carburetor is tightly mounted, or remove carburetor to check gaskets. Replace if necessary (I’ve used a cutout from a cereal box in a pinch) |

Stale Fuel Can Cause Your Generator to Stall When the Choke is Opened

This is a pretty simple thing to diagnose and fix.

Think back to the last time you put fuel in the tank. Was that fuel treated with stabilizer like SeaFoam or Stabil?

If the answer is over one to three months and you did not stabilize your fuel, then it has gone stale and is much less combustible than it once was and can lead to engine stalling. Follow the remaining advice below and then proceed to the next section.

If you did treat your gasoline with stabilizer and it has been under 12-15 months, then you’re probably in the clear. You can likely skip to the next section.

To drain out old gas, first, turn off the fuel valve to isolate the carburetor from the fuel tank. Then, typically using a 10mm wrench, open the drain screw on your carburetor if it has one and make sure to place something underneath to catch the gas.

Now, find an empty fuel container and find where the fuel line attaches to the carburetor. From there, disconnect the fuel line (you’ll need pliers to move the clamps) and place the fuel line in a funnel or directly into the gas container if it can reach.

Turn on the fuel valve and let the tank empty.

Because you’ve had the pleasure of leaving stale gasoline in your tank, it has done what untreated gas does when it oxidizes — turn to varnish. Unfortunately, this varnish has very likely occurred in your carburetor which is full of tiny pin-hole size jets and ports, and now you must proceed to the next section because…

A Carburetor’s Main Jet is Clogged and Causing a Stall with the Choke Off

Before gasoline can be drawn up from the bowl of the carburetor and mixed to the proper fuel-to-air ratio to be pulled into the intake, the gasoline must first pass through the main jet. From there, it is diverted through a series of ports and other jets depending on whether or not you’re on idle or full throttle.

Because your main jet is the lowest jet (vertically speaking), it is most likely to have been gummed up by oxidizing fuel in the carburetor bowl.

Luckily, this is an easy fix and you can probably take care of it without removing your carburetor.

First, shut off the fuel valve. If your carburetor bowl has a drain screw, use a 10mm wrench to open it and allow any fuel in the bowl to drain out. It shouldn’t be much.

Now, remove the main bolt/nut at the bottom-center of the bowl and remove the bowl. Take note of the condition of the rubber gasket between the bowl and the carburetor while you’re doing this, and be careful not to pinch the gasket when reassembling.

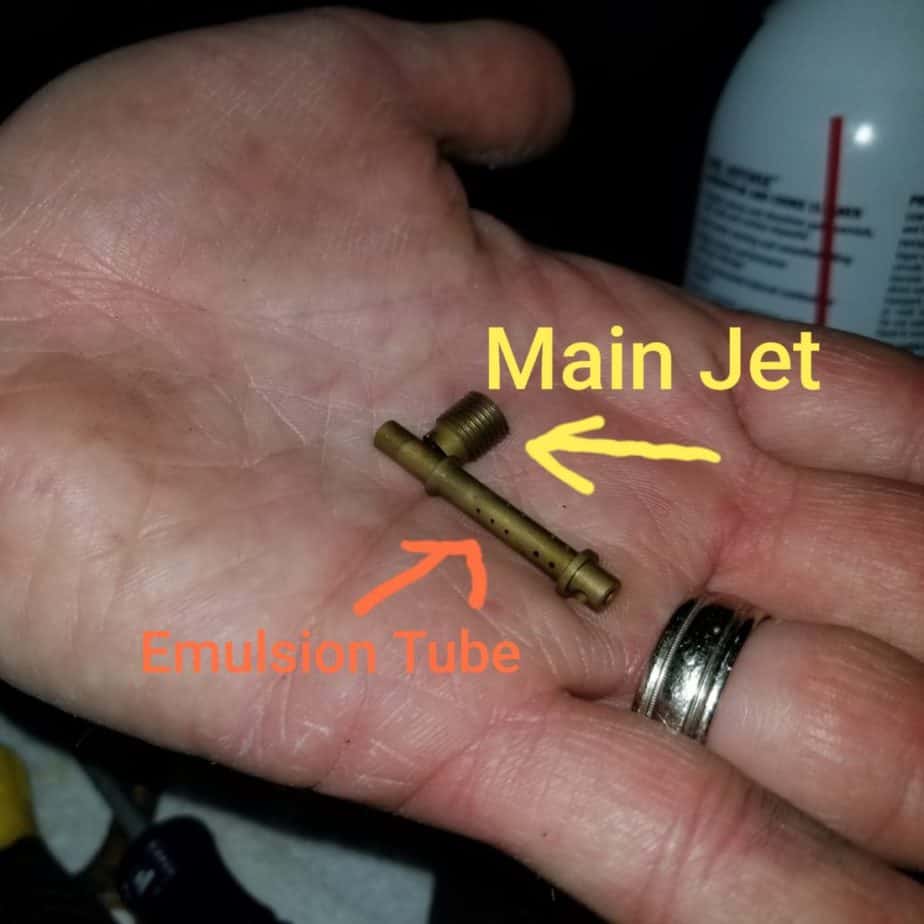

With the bowl removed, use an appropriately sized screwdriver to remove the main jet. You may have to file a screwdriver down to fit if it’s too big.

Conversely, having one that is too narrow is likely to damage the brass jet when you try to turn it and the screwdriver won’t have even pressure on both of the slots that it should fit into. I’ve ruined the head of the jet before, and once you do it there is no fixing it.

With the jet and emulsion tube removed, you’ll likely see no daylight through the small pinholes, or they will be restricted by a varnish substance. Using a single bristle from a wire brush or burning the paper/plastic off the end of a twist tie, ream out the holes in the jet and emulsion tube.

If you have carburetor cleaner spray, now would be a good time to spray everything for good measure. If not, you’ll probably still be fine for now.

Reassemble everything and more than likely you’ll be back in business. If not, let’s quickly clean out the pilot jet.

A Clogged or Restricted Pilot Jet Will Cause Stalling With the Choke Off

On many carburetors, the gasoline has to first pass through the main jet and is then diverted through the idle circuit to the pilot jet. If we’ve established that the main jet is now clean but there is still a problem, we’ll need to verify that the pilot jet is now clean.

The pilot jet allows the gas to pass through and mix with the air while the engine is at idle (regardless of the choke being on or off).

On many carburetors, it is located right below the throttle adjustment screw on the outside-top of the carburetor. There may be a plastic insert sitting on top of it.

First, remove the throttle adjustment screw but before you do that you will want to screw it in all the way and count how many turns. Then, later when you put it back, screw it in all the way and back it out that many turns so that you’ll be where you started.

Then, remove the plastic insert (if it has one). This just pops up by hand or by gently prying with a flat head screwdriver.

Then, unscrew the pilot jet beneath it. The large tubes that run laterally through the screw will almost always be fine, but the small brass hole on the bottom of the screw can easily get gummed up or clogged.

Clear out the obstruction and reassemble.

If you’re still having issues, we’ll try one more thing before we might have to throw in the towel and take it to a professional. We’ve been focusing on the fuel being restricted relative to the amount of air. Now, let’s see if we have an excess of air.

Damaged Gaskets or a Loosely Mounted Carburetor Can Cause Stalling with the Choke Off

These go hand in hand and both result in the generator sucking way more air into the intake than there is fuel to mix with and will lead to stalling.

If your carburetor is not tightened properly to the intake, it will cause a vacuum between the two and the intake to the combustion chamber will suck in far more air than it knows what to do with.

Likewise, if your carburetor is tight against the intake but the gasket between the two is ripped or damaged, it can cause the same effect and you’ll end up stalling due to having too much air being sucked in the engine.

Tighten everything up properly and replace any gaskets that are compromised.

How to Prevent this from Happening Again

There you have it! I’d say that there is a 95% chance that you’ve solved your problem. If the issue was with the top two causes, make sure you use only stabilized fuel and change it out after 1 year. Place a piece of duct tape on your generator and gas can and write the date of purchase and whether it’s treated or untreated with a marker.

I recommend ethanol-free fuel if you can help it as it helps to prevent water in the air from being attracted to your fuel.

When you shut off your generator for storage, turn the fuel valve off while the engine is running to allow the carburetor to use up the remaining fuel in the bowl and preventing this fuel from oxidizing around your main jet.

Best of luck with your power outage and I hope the next time you need to start your generator it’ll be a lot easier!