Nothing is as wacky as noticing that your house isn’t cooling only to go outside and see your air conditioner’s compressor posing as a block of ice on a hot summer day! At first glance, it almost seems impossible!

Unfortunately, it’s a very real scenario and can happen for a myriad of reasons. Some of these reasons can easily be addressed by any homeowner, some take a little skill, and some require a professional to diagnose.

In this article we’re going to talk about the three things you can easily do to fix an AC system that has turned to ice. I’ll also mention two things you might be able to tackle if you’re handy.

I spent the last 4 years servicing HVAC systems on a weekly basis at my previous job as a maintenance technician and I just want to provide a basic understanding to the beginner about why your system is freezing, what you can do to fix it, and when you need a professional.

Grab a cup of coffee and let’s get started!

Why Does an HVAC System Freeze?

This will make more sense to you if you know the basic principles of how an AC system works on a high level. If you are new to air conditioning, click here where you’ll scroll to the bottom of this article for a quick summary, and then you can click back once you understand.

Okay, assuming that we’re on the same page, let’s get to the meat and potatoes of the article.

An HVAC system will freeze and turn to ice when the refrigerant in the lines becomes too cold and cannot absorb enough heat from the ambient air inside the building that is being cooled. This causes a domino effect where the evaporator coils will freeze the moisture in the air that condensates on the coils (and fins) and then they will freeze the lines all the way back to your compressor outside and the compressor can freeze as well.

Generally, an HVAC system will freeze when airflow is restricted due to a clogged furnace filter, a malfunctioning blower motor (or control board), return vents being blocked, a clogged evaporator coil, or the thermostat being set too low.

Let me break down the vicious circle below with made up numbers that will get the point across:

Essentially, since the evaporator coils (which have a very cold refrigerant in them — let’s say 37 degrees Fahrenheit) are not able to absorb enough heat from your house efficiently enough because of a clogged air filter, for example, the still cold refrigerant then moves to the compressor outside in a colder state (let’s say 39 degrees) instead of a warm state (47 degrees, for example). In this case, the evaporator coils absorbed 2 degrees of heat instead of 10 because there wasn’t enough airflow.

This 39 degree cold refrigerant is then compressed and made hot at 110 degrees (but not as hot as it could be if it had absorbed heat from your house, where it may have been 120 degrees) as it enters the condenser coils. The condenser fan causes the ambient air outside to cool off the hot refrigerant by 10 degrees, for example. The refrigerant is now cooler than it otherwise would have been (100 instead of 110 as a final temperature) and it then goes back into your house.

Once the 100 degree warm refrigerant (10 degrees cooler at this point than it should be because it never absorbed your home’s heat to begin with) arrives at the metering device right before your evaporator coils, it drops in pressure and becomes cold again (colder than it would have been had it absorbed heat the last time it passed through). Instead of dropping it 37 degrees this time, it might drop to 27 degrees, for example.

Once your coils are below the point of freezing and there is not enough warm air cycling through them to warm them up, then the condensation in the air will freeze on the coils as they become colder and colder as long as the compressor remains turned on.

Ice will build and build until the evaporator coils are a block of ice and then the condensation on the lines leading outside will freeze. Finally, if you let it go too long, the compressor itself will freeze.

Once again, the numbers used above were to make a point, not to be an exact HVAC science.

What to Do If My HVAC System Has Frozen to Ice?

If you notice that your HVAC system has turned to ice, adjust the thermostat so that the blower motor fan remains on (fan on continuous) to aid with the ice melting but make sure the AC is turned off. Allow the evaporator coils, lines, and compressor to completely thaw. Do NOT chisel at the ice with anything as you risk puncturing the coils which will lead to a very costly replacement.

When your system freezes, you’ll also want to make sure that your condensation drain pipe isn’t clogged (but it may be frozen as well, in which case you can’t do anything about it). I’ve had this happen to me before when my system wasn’t even frozen and my evaporator coils were sitting in a pool of water.

Keep in mind that your condensation drain pipe will not handle all of the melting and you’ll definitely have water around your unit, so have towels all around it to mitigate water damage.

I’ve worked on about 6 HVAC systems that had frozen at the properties I was called to and none of them suffered any long term damage from the ice expansion on the coils or tubing. I’m sure it can happen, but don’t be a pessimist just yet!

Before you turn on your AC again, make sure you diagnose why your system froze in the first place. We’ll cover that in the next section.

4 DIY Solutions to Fix an HVAC System That Has Frozen to Ice

Here are some things you can check without any technical knowledge to fix an HVAC system that has turned to ice. Thankfully, as long as your system was working properly at one time, these will likely be your solutions!

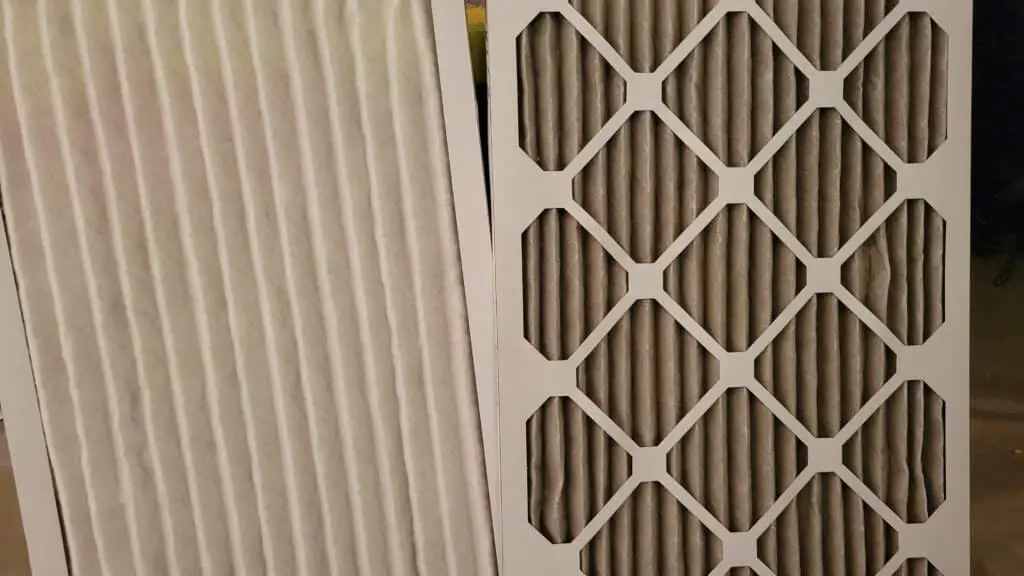

Dirty Furnace Air Filter

This is going to be the first thing you should check. A furnace filter should be replaced at least every 3 months on average. If you are asking, “what furnace filter?” then this is likely your issue!

Somewhere to the side or above your furnace’s blower motor is a narrow slot where you will be able to slide in a filter. Go ahead and remove the old one and slide in a new one, but make sure that the directional arrow is pointing the right way. The arrow should point towards the blower motor.

The reason that a dirty air filter will cause your system to turn to ice is that the dust in the filter restricts the amount of air that can be blown to the evaporator coils. If the coils don’t have enough warm air from your house blowing over them to absorb the heat, then the refrigerant will get progressively colder and colder until it starts freezing the moisture in the air that condensates on the cold coils.

Return Vents are Obstructed

If you recently moved some furniture around or if you had a family member put a piece of cardboard over what they thought was a normal vent in an attempt to block any cold air, then you might have an obstructed return vent.

These vents will not have an adjustment slider on them (they are fixed open), just in case you don’t know the difference between them and a normal register where the cold air flows into your room.

The blower motor needs enough air coming back through the return vents in order to cycle the room’s air through the evaporator coils. If you block enough of the return vents, there won’t be enough warm air from your room passing by the coils to warm them and, just like above, they will start to freeze the moisture in the air that condensates on the coils.

If you’ve got any obstructed returns, make sure to open them up for proper airflow.

Thermostat Set Too Low

The general rule of thumb is not to go below 67 or 68 degrees when adjusting your thermostat. If you do, you risk having your coils freeze up.

Once again, the reason is similar to those above.

Once you lower the temperature in your house below a certain level, the air is cold enough now in your house that it no longer provides enough warmth for the coils to absorb as the room-temp air is blown over them. Cold air is now passing over cold coils, and there isn’t the heat transfer that’s required to keep the refrigerant system stable.

Outside Temperatures are Below 60 Degrees Fahrenheit (15.55 Celcius)

This one is sometimes hard to do, as your system may have a sensor that won’t allow it. If yours does turn on when the outside air is below 60 degrees, you risk cooling off the refrigerant too much as it passes through the condenser coils outside. The compressor also has to work harder because the lubrication inside isn’t as fluid and “stiffens up” in colder temps.

The condenser fan outside draws in the ambient sub-60 degree air and cools the coils but the result is that it cools the refrigerant too much (and lowers the pressure in the line). Now, when it goes back to the metering device and evaporator coils, it is even colder than it should be when compared to the temps needed to keep the system stable.

If the air in your house isn’t extremely warm (I’m assuming it’s not since the outside temps are so low), then there won’t be enough heat in the air to warm up the even colder refrigerant in the evaporator coils and, once again, the coils will freeze the moisture in the air that condensates on them.

When You Will Need a Professional to Diagnose Your Issue

The aforementioned items can easily be fixed by anyone, but the following situations will likely require professional assistance.

Low Refrigerant

As we mentioned in the section below that gives a breakdown of how an AC system works, lower pressures in the refrigerant lines will equal lower temperatures.

If you are low on refrigerant then there is less pressure inside the lines. Therefore, the temperature throughout the system will naturally be lower than it otherwise would be.

If you’ve ruled out the DIY fixes above, you will need to hire a professional with special guages to measure the pressure in your lines. They are licensed to do this and are the only ones permitted to be in possession of the refrigerant as well.

I had this situation happen at one of the properties I worked at. At first we thought it was a dirty air filter. We changed the filter, let the system thaw for a couple days and turned it back on. It worked well on certain days at certain temps, and would turn to ice on other days. The result was low refrigerant levels. Once refrigerant was added, the problem stopped entirely.

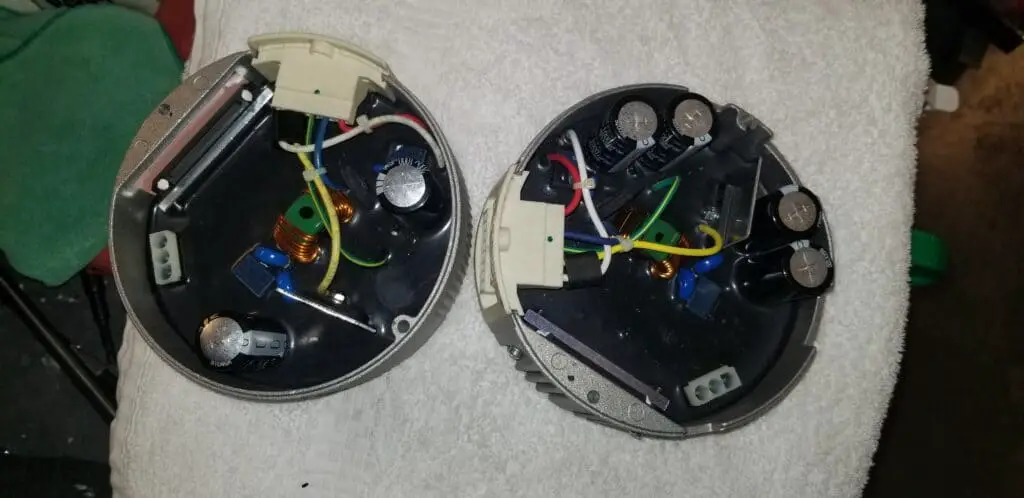

Blower Motor or Control Module on Motor is Defective

If you have a blower motor go bad, or the module on the back (some models) becomes defective, then you’ll need to get a new one installed.

When a blower motor fails, the evaporator coils will no longer have warm air from your house blowing over them. Within minutes they will drop below the freezing point and will start freezing the moisture in the air that condensates on them.

If you’re handy, and if you have a store that will sell them to you, you may be able to replace the blower motor or control module by yourself. Some stores will only sell to licensed professionals.

Though I wasn’t licensed at my previous job, I did have a store that would sell to me and I replaced several motors and control modules over the years at various properties. It’s not hard, but it does require a basic working knowledge of what is what and there are certainly safety issues to be aware of.

Control Board Defective

If the control board stops sending a signal to the blower motor to turn on, then the evaporator coils will freeze up very quickly just like I outlined above.

There’s usually not much you can do to fix one except to replace it altogether.

This can be done by yourself if you’re handy and know what you’re doing. You’ll also need to find the exact make and model replacement so that you’ll be able to plug everything back into it without any extra wires.

Make sure to take lots of good photos of your board before you start unplugging things!

If you’re not comfortable with this, I recommend calling a professional to diagnose and replace if this happens to be the issue.

From my experience, I had about 10 blower motors (or their corresponding control modules) go bad compared to a single control board going bad over the course of 4 years at several properties. It can happen, but it’s probably lower on the checklist of potential problems.

Metering Device Obstructed

This one will be strictly for professionals. Once you’ve ruled out the DIY fixes, a professional will then rule out the reasons above as well. Once that’s done, they will likely check the metering device for any obstruction.

If debris is in the line and partially obstructs the tiny hole that the refrigerant passes through as the pressure is reduced (and therefore the temperature), then even less refrigerant will enter the evaporator coils and with less refrigerant in the line the pressure (and therefore temperature) will be lower to the point where it will drop below the freezing point.

This would be a rare scenario in my experience. I had all of the aforementioned cases occur at my place of work or a neighbor’s house over the years but this is the only one that I never encountered.

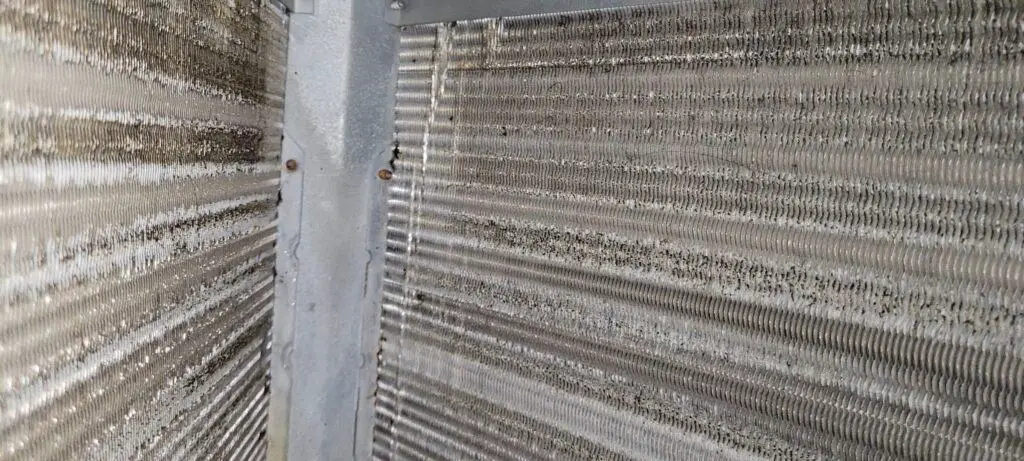

Evaporator Coils are Dirty

This goes hand in hand with a dirty air filter, but this one is definitely harder to access and will almost always require a professional unless your unit has a convenient access panel.

If your furnace filter became too dirty in the past where dust eventually skirted around the filter itself because air couldn’t flow through it, or if you were missing a furnace filter for a length of time, then you can definitely have evaporator coils that are caked with dust and no longer have enough air flow through them to allow the warm room temperature air to pass through the coils and warm up the refrigerant.

Keep in mind that when I say “coils”, there are indeed actual copper pipes that make up the coils but these coils have tons of fins attached to them (like on a car radiator) to help absorb heat from the air passing through them. Because these fins are so close together, it’s easy for dust to collect and block the airflow between them. Once this happens and the temp drops, the water vapor in the air that condensates on the fins and the dust will freeze.

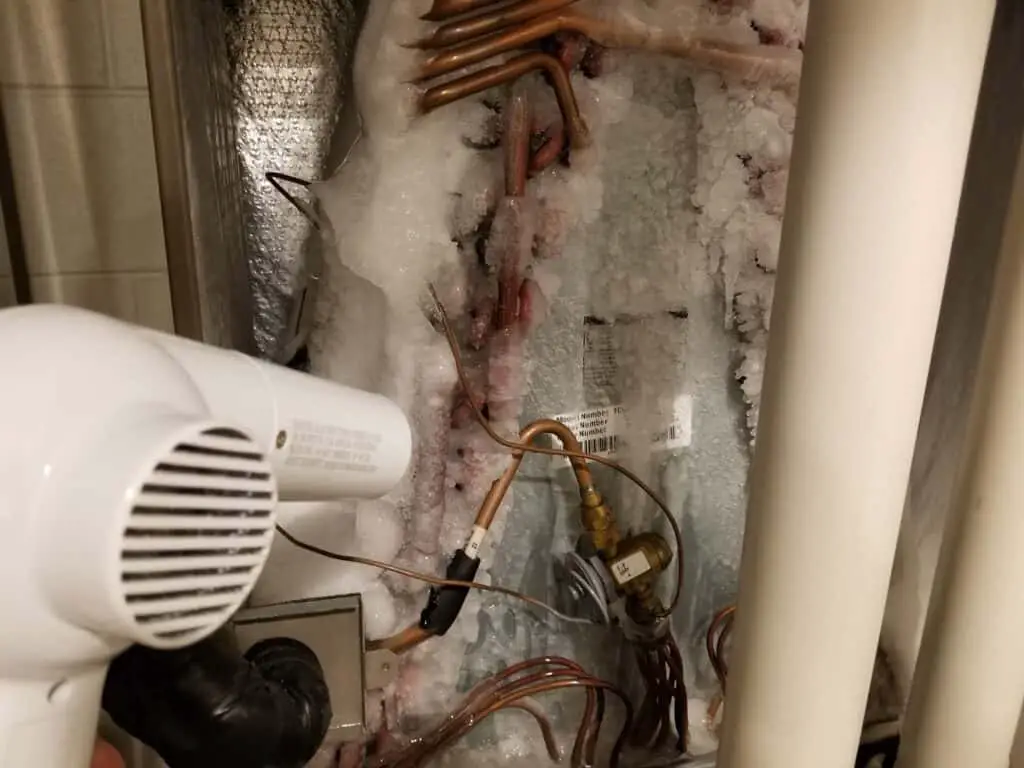

Can I use a Blow Dryer to Thaw a Frozen AC Unit?

You can use a blow dryer to help melt any ice that has accumulated on your HVAC system but you should be cautious that as it melts it will likely be pooling around the unit and you’ll be standing in water while holding an electric device. Granted, all modern blow dryers have a GFCI plug built into them, but you should still be cautious.

In my honest opinion, using a blow dryer to try to melt the ice on a frozen HVAC system is a waste of your time on this earth. It’s cathartic, more than anything. The effect you’ll have is a drop in the bucket compared to the amount of ice that you can’t even see once you start working on it.

DO NOT, under any circumstances, chisel away at the ice with anything. You risk easily puncturing the thin copper tubing on your system and once that is done you’ll be facing hundreds (if not thousands) of dollars in repairs, replacements, and recharging the refrigerant.

I recommend just letting it melt naturally but to keep the blower motor turned (fan on constant, AC turned off) to help with blowing warm household air over the ice. Depending on how frozen your unit became, it could take anywhere from 1 to 2 days to fully melt.

How Does AC Work?

Understanding why an HVAC system turns to ice makes the solutions mentioned afterward make perfect sense. To understand why it turns to ice, we need to first cover how an AC system works (don’t worry, I’ve got you covered!).

If you’re new to how air conditioning works, we’ll keep it high level and easy to understand.

Keep these things in mind:

- Higher Pressures = Higher Temperatures

- Lower Pressures = Lower Temperatures

- Convection = Air passing by something to steal away heat

- Colder things will always steal away heat from warmer things

Your refrigerant (or what many call Freon) is in a closed system that circulates in your house and back outside. This refrigerant is very sensitive to temperature changes when it undergoes pressure changes.

The purpose of this refrigerant is to absorb heat from the air inside your house and dispel the heat when it travels outside.

Here’s how it works.

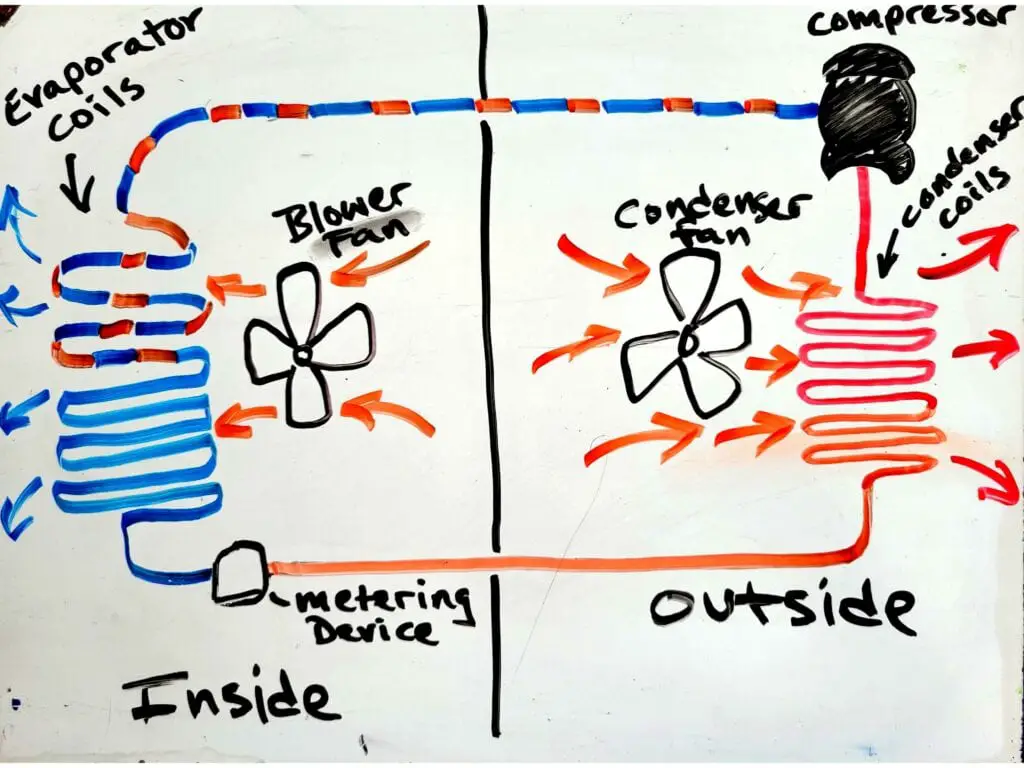

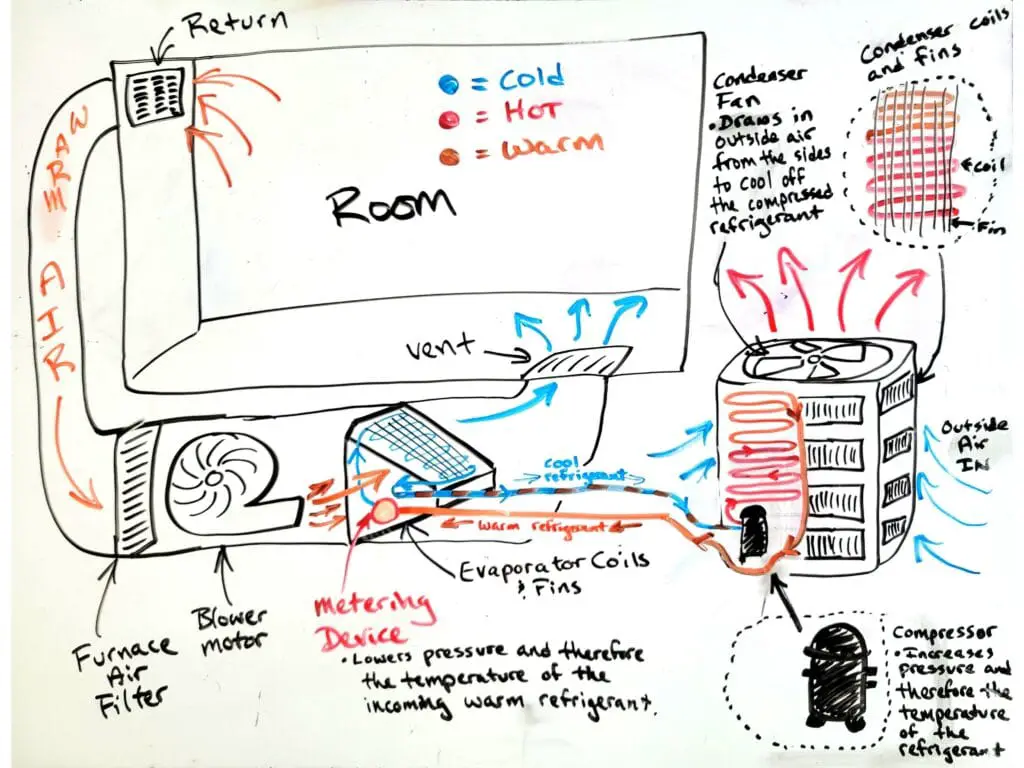

When your thermostat calls for cold air to cool off the house, it triggers the blower motor inside your house (by your furnace) and it also triggers the compressor and condenser fan outside. These are the basic moving parts that keep this system working on a high level.

We have a fan indoors, a fan outdoors and a compressor which acts as the pump that keeps the refrigerant moving through the closed system.

Both fans are used to create convection over a set of coils that they are blowing their air on. Convection is when you sit next to a fan after working out and immediately feel cooler because the fan is blowing cooler air by your skin and the air itself steals your heat away as it passes by you. These fans do the same thing to their respective coils.

As the compressor compresses (I know, it’s got a unique name, right?) the refrigerant as it enters the condenser coils outside, it becomes hot because higher pressures will result in higher temperatures. The temperature of the refrigerant will exceed the ambient temperature outside but still needs help with cooling off.

That’s where the condenser fan comes into play. It draws ambient air outside through the coils and discharges the air at a high rate of speed above the unit. If you place your hand over your HVAC unit outside on a 90 degree day, you’ll notice that the air blowing up at you is even hotter. Basically 90 degree air got sucked through the coils by the condenser fan and is now exiting the unit at 100 degrees (just spit balling a number).

The refrigerant just cooled off by 10 degrees in this example. That heat that was released into the air outside was heat that was absorbed from the air in your house.

As the refrigerant cools off, it travels back into your house and to the evaporator coils in your house (attached to your furnace and just downstream of your furnace’s blower motor). When it gets to the coils it’s still too warm to cool off any air in your house.

The refrigerant passes through a metering device right before it enters the evaporator coils. This metering device restricts the amount of refrigerant that can enter at one time into the coils and this reduces the pressure greatly. As we mentioned before, lower pressures will result in lower temperatures.

Refrigerant is special because it will go from warm/hot to very cold in an instant with this simple pressure change.

As the very cold refrigerant fills up the evaporator coils, the furnace’s blower motor blows warm household air through the coils and the cold refrigerant absorbs heat from the household air.

As the household air exits the evaporator coils it is then pushed to all of the rooms of your house as air that just had heat removed from it (so it feels colder, maybe by 10 degrees colder if we want to stick with that number for this example).

The now warmed refrigerant (by 10 degrees) passes back outside where it is compressed to be even hotter and the cycle starts all over again.

Now that you’ve got it, click here to jump back where you left off.