Nothing can add more stress to a power outage than a generator that isn’t functioning properly. One of the most common issues to plague generator owners is the dreaded “surge” or “revving up and down” of the engine.

This can happen when the generator is under load or when it’s simply at idle.

As a general rule, a portable generator will surge at idle due to a clogged or restricted pilot jet on the carburetor. When the generator is under load, it will often surge due to the governor spring being disconnected, a restricted main jet in the carburetor, or stale fuel.

Those are the big reasons, but there are, however, several other common reasons and I’ve got them in a table below. Thorough explanations can be found for each one below as well as a video guiding you through all of this.

Thanks for stopping by, and let’s get started!

| When Generator Is Surging (Idle, Under Load or Both) | Possible Cause of Surging | How to Fix |

|---|---|---|

| Both | Stale Fuel — can’t combust properly to keep up with any engine speed | Drain Fuel and Replace |

| Idle | Pilot Jet Clogged or Restricted — not enough fuel can get through the low speed jet for idle purposes, however, engine may run perfectly under load | Remove throttle adjustment screw, pull out pilot jet if possible (might be fixed), bore out pilot jet with a small wire. Spray in carburetor cleaner with a straw if fixed. |

| Both | Missing or Detached Throttle Spring — spring takes up any of the slack from the governor arm and throttle linkages and smooths out any changes in RPMs, without it RPM changes are choppy | Reattach or replace |

| Both | Fuel Selector Switch is bad (only on certain duel fuel models) — defective switch is restricting fuel flow to the carburetor | Bypass switch. Turn off fuel petcock (fuel valve), detach fuel hose from petcock, detach fuel hose that runs from fuel selector switch to the carburetor and hook it up to the fuel petcock. Hook the original fuel petcock hose back up to the fuel selector switch so that it loops back on itself. |

| Under Load | Main Jet is Clogged or Restricted — not enough gas is allowed in the the combustion chamber fast enough for the load | Shut off fuel valve, drain carburetor bowl, remove bowl, clean out main jet and emulsion tube with carburetor spray and a small wire. Carburetor may or may not need to be removed depending on your model and access to the carburetor. |

| Under Load | Fuel Filter or Screen (inline, in the tank, screen in the fuel petcock, etc.) is clogged or restricted — not enough gas getting to the carburetor fast enough for the load | Locate any place between the carburetor and the tank (including the inside of the gas tank) that has a filter or screen and make sure they are clear |

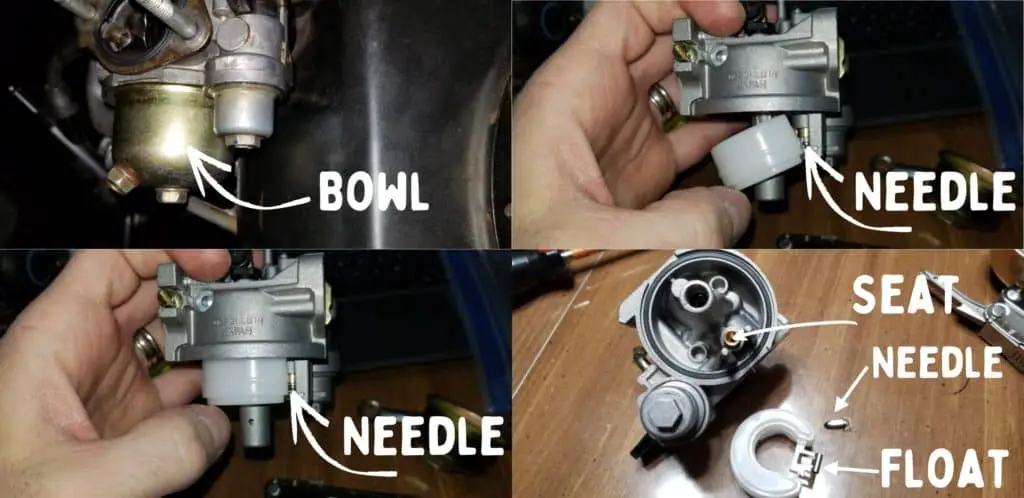

| Under Load | Float in Carburetor in Top Position Prematurely — float needle is malfunctioning and causing the float to close the needle valve prematurely so not enough gas is available in the carburetor bowl to keep up with the load | Shut off fuel valve, drain carburetor, remove air filter assembly, remove carburetor, remove carburetor bowl, remove float and needle assembly. Clean or replace everything if needed. Float should be parallel to the bowl gasket when in the top position. |

What is a Surging Generator

To keep it simple, a generator can surge while it is running at idle (under no load), or at higher speeds (powering appliances under load).

The surging can be caused by stale fuel, clogged or restricted jets in the carburetor, a problem with the carburetor float, or by an issue with the linkages to the carburetor and their corresponding springs — just to name a few of the major causes.

The sound that a generator makes when it revs up and down is due to inconsistent fuel being delivered to the engine.

The generator is starving for and “hunting” for fuel. When it gets a spurt of what it needs the RPMs of the engine cycle up for a second, and then when it can’t get enough again the RPMs drop for a second. This process repeats over and over again usually in a rhythmic pattern.

What Causes a Portable Generator to Surge (No Load / Idle)

When your generator’s engine is running at idle, it is not powering any devices. The engine is simply doing the bare minimum required in order to keep itself operational.

Under this circumstance, it should be running smoothly without any noticeable deviations in engine speed.

A generator’s carburetor has two primary “circuits” depending on what is being required of the engine — Idle, and High Speed.

When on the idle circuit, vaporized gasoline and air take a different route through the small passages of the carburetor than they would if the generator were powering appliances and working harder while under load.

A fix for a surging generator while it is under load is not necessarily what will fix a generator that is revving up and down at idle.

The most common reasons for a generator to not run smoothly while at idle include:

- Stale Fuel

- Pilot Jet Clogged or Restricted (Usually the problem at idle)

- Missing or Detached Spring between the carburetor and governor arm

- Fuel Selector Switch is Defective (only for certain models that are duel fuel capable)

How to Fix a Surging Generator (No Load / Idle)

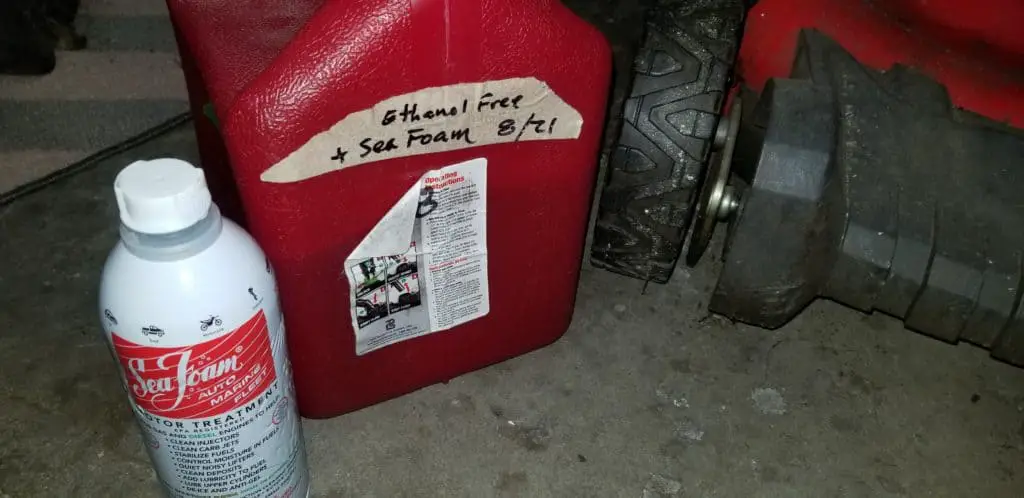

If your gas has not been treated with a fuel stabilizer and is older than 3 months, you should disconnect a fuel line and drain it or pump it out with a battery operated fuel pump. At this point, the gas has likely gone stale.

Refill with fresh fuel, and be sure to use a fuel stabilizer like SeaFoam when you purchase the gas. Just mix 1 fluid ounce per gallon in your gas can and then it will store in the can and in your generator for up to 2 years.

I’ve tested the 2 year claim and it absolutely works.

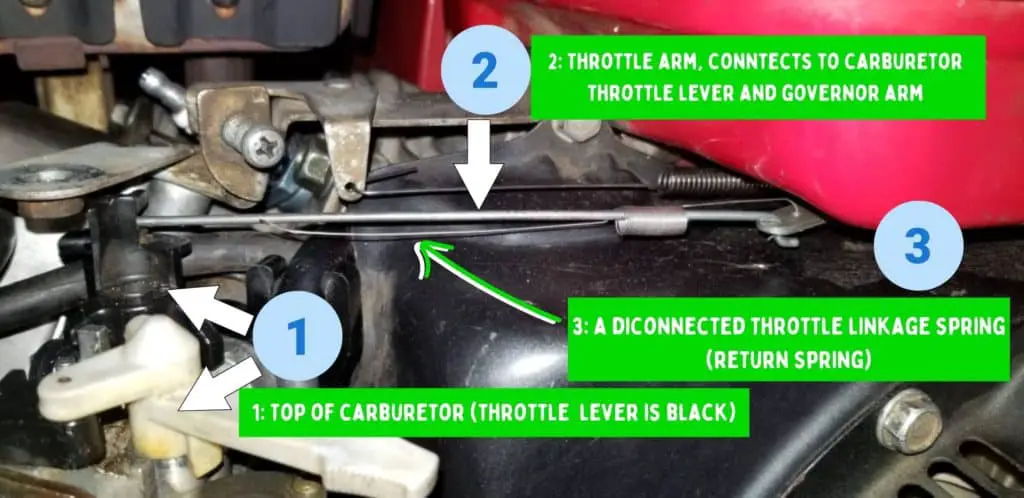

An easy to overlook problem is a missing spring that rides alongside your throttle arm (between the governor arm and the top of your carburetor). These often have their end break off and they are just floating in place, or they are missing altogether — especially if you bought your generator used.

Check out the picture below. If you don’t see one, replace it. If it’s disconnected or broken near the end, go ahead and reattach or make a new hook and reattach. If you have to make a new hooked end with a pair of pliers, you may have to stretch out the spring just a little at one of the coils so that it isn’t too tight.

Usually the problem lies with the pilot jet being clogged or restricted and this won’t allow enough fuel to get to the engine. The result will be a rhythmic surging.

You likely don’t have to remove the carburetor for this problem. Screw in the throttle adjustment screw and count the number of full turns. Write it down and then unscrew it all the way out.

Use a pair of pliers to gently lift out the pilot jet.

There will be a hole that runs laterally through the piece that you just pulled out and that is for air. On the bottom tip of that piece is a pinhole that easily gets clogged — especially if the gas was stale.

Burn the plastic or paper off the end of a twist tie and use that to poke through the small hole to clear out any blockages. You should see the wire when you look through the larger air hole.

Cleaning out the pilot jet will clear the majority of your problems with a generator that surges at idle.

Top Left: Throttle Adjustment Screw; Top Right: Pilot jet being removed from below the throttle adjustment screw; Bottom Left and Right: Using a twist tie wire to clean out the jet

Pro Tip: If you check off all the possible causes in this article as not being the problem, you may have to bore out the pilot jet ever so slightly with a micro drill bit or even with a small torch tip cleaning file. This may be needed with newer generators after the engine has finally broken itself in.

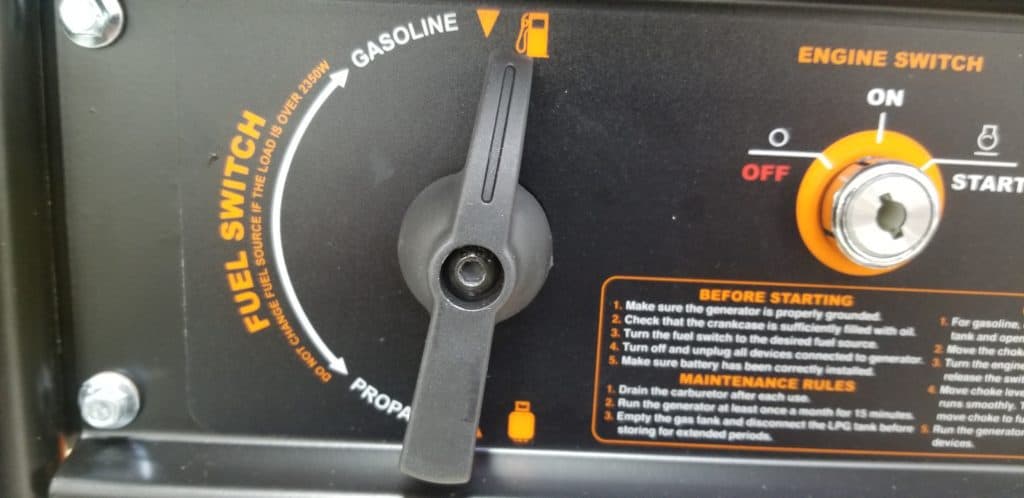

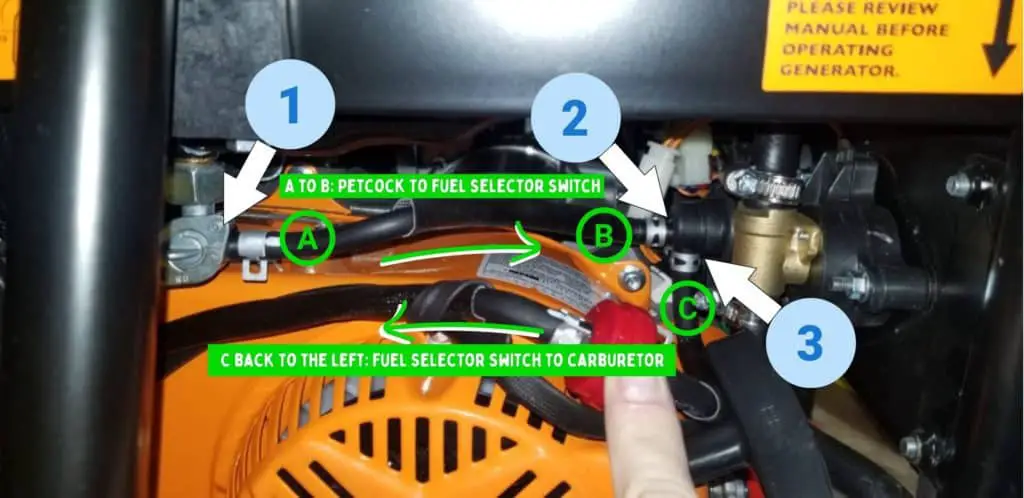

Now, if it’s still surging at idle (or under load) and you have a duel-fuel generator (it can use propane or gasoline), you may have a defective fuel selector switch which is preventing proper flow to the carburetor.

Go ahead and turn off the fuel valve (petcock). Then remove the fuel line from the petcock but leave the other end attached to the fuel selector switch.

Now, remove the fuel line from the fuel selector switch that runs to the carburetor and hook it up to the petcock itself. Now you’ll have a direct line that runs from the gas tank to the carburetor.

Plug the loose end of the fuel line back into the fuel selector switch so that it doubles back on itself.

Make sure to set the switch to gasoline before starting. You’re simply bypassing the switch.

What Causes a Portable Generator to Surge (Under Load)

When the generator is running under load, it is not using the same passageways in the carburetor that were used when it was at idle.

The generator is now requiring a massive amount of air and gasoline in order to power your appliances, compared to when it just needs to idle enough not to stall.

Anything that blocks or restricts the adequate flow of gasoline down to the carburetor and up to the combustion chamber can cause revving of your engine as it hunts for fuel.

Primary causes of surging for a generator under load include:

- Stale Fuel

- Clogged or Restricted Main Jet

- Missing or Detached Throttle Spring

- Float is Closing the Float Needle Valve Prematurely

- Any Filter or Screen from the Carburetor to Inside the Gas Tank is Clogged or Restricted

How to Fix a Surging Generator (Under Load)

As we mentioned earlier, if you suspect that your fuel is stale (3 months or older and hasn’t been treated with a fuel stabilizer), go ahead and disconnect a fuel line and drain the fuel out and replace.

One of the more common problems will be a clogged or restricted main jet when you are running under load.

For this you’ll need to possibly remove the carburetor itself by first removing the air filter assembly, the linkages, and turning off the fuel valve.

You might be able to leave it on, it just depends on your access to it.

Either way, the fuel has to be turned off and the bowl of the carburetor needs to be drained and removed. When that’s done, the main jet might be built into the bolt that holds the bowl on, or it might be up in the main tube that sticks down into the bowl. If it’s in that tube, you need to remove it with a flat-head screwdriver and be very careful not to strip the head since it’s made of soft brass.

Clean the main jet and emulsion tube with carburetor cleaner spray and a small wire to make sure all of the holes are clear. Reinstall everything and try running the generator again.

Cleaning the main jet will take care of the bulk of your surging issues under load.

Of course, like before with the idle issue, be sure to check to spring that runs parallel to the throttle arm and make sure it’s not missing and properly connected.

(See Picture in “Idle” section above for a visual)

A rarer occurrence, but still certainly possible, is that your float in your carburetor is closing the float needle prematurely due to a faulty float needle valve.

The float might be closing prematurely but still supplying enough gas for idle operations, but under load, when more gas is required, the defective float will lead to revving, surging, or stalling.

If the float is closing off the flow of gasoline into the carburetor too early, then when the engine calls for more fuel to power your appliances, it will quickly burn through the limited amount before it can refill again. It’s like trying to run full speed but only breathing in 1/4 of the way but still breathing that way as fast as you can.

To check this, turn off the fuel valve to the carburetor and remove the carburetor bowl. Very gently push up on the float until you no longer see the needle moving up.

If the “top” position of the float is NOT parallel to the bowl gasket (perfectly horizontal), then you should definitely remove the float and the float needle assembly for cleaning or replacing. It’s not uncommon for the float needle (rubber tipped) to get deformed, or for a rubber seat to swell up or rip.

The needle and seat will be one of the two combinations:

- A rubber-tipped needle with a brass or metal seat, or

- A metal needle with a rubber o-ring in the seat

Finally you might have a clogged or restricted screen or filter anywhere along the path of the gasoline from the tank to the carburetor.

There could be a screen or filter in any of the following locations, but most generators only have 1 or 2:

- Inside the gas tank there’s a screen on the pickup tube

- An inline fuel filter

- The fuel petcock (fuel valve) may have one

- The tube on the carburetor that the fuel line connects to may have one inside

If your tank has a screen on the end of the pickup tube for the gasoline, it may look perfectly clean from outward appearances. If you have used untreated fuel in your generator, however, you could still find that is 75% clogged with varnish despite the clean appearance.

If you drain the tank and then remove the fuel petcock below the tank, you should be able to remove this tube and screen.

Try blowing through it. If you are meeting a lot of resistance, it needs to be replaced. You could also try soaking it in a couple ounces of SeaFoam to see if that clears it up as well. I’ve never tried it, but SeaFoam will eat away at the varnish and it’s worth a shot.

If you have an inline fuel filter, they are easy enough to replace and disconnect to check for debris. Again, if you blow through it, you shouldn’t be meeting resisitance.

A lot of Honda engines that I’ve serviced over the last 7 years have had screens built into the fuel shutoff valves (petcocks) when the valve is attached to the carburetor.

Just remove a few screws holding the plate above the valve and you can access it from one way, and you can also unscrew the bowl at the bottom of the petcock as well to access the screens.

Finally, you might have a screen in the tube on the carburetor where the fuel line connects. If so, remove the tube by twisting and pulling straight back with a pair of vice grips.

Once removed, the screen will be visible in the hole in the carburetor. Go ahead and clean it off and push the tube back on the same way.