You should be outside finishing up your lawn but you find yourself here wondering why your lawn mower sounds more like a popcorn machine with all of its backfiring and popping and less like a smooth running engine.

I won’t bore you with some intro you’re not going to read anyway, so let’s jump right in to why this is happening and what you can do about it.

One very quick thing before we continue. There is a difference between “backfire” and “afterfire” and it all depends on where the popping sound originates. If it’s coming from the exhaust, it is known actually as “afterfire”. If the sound is coming out of the carburetor and air filter, then you are experiencing “backfire”.

For the sake of this article, I am going to lump them all into “popping” sounds and label them all under the term “backfire” since that is common language expressing the same general concern.

As a general rule, push mower will backfire or make popping noises if the air filter is clogged, the jets in the carburetor are clogged or if the fuel is stale. If the problem persists beyond the easy repairs, then a sheered flywheel key, a bad ignition coil, or incorrect valve clearances are likely causes.

Generally, a riding lawn mower will backfire or make popping noises if the air filter is clogged, jets or o-rings in the carburetor are compromised, or if the fuel is stale. Common but more technical reasons beyond that include incorrect valve clearances, faulty ignition coils, a bad spark plug (2-cylinder engines) or a sheared flywheel key.

| Type of Mower | Reasons for Backfiring (Popping) |

|---|---|

| Clogged Air Filter Jets (Pilot and/or Main) in Carburetor Clogged Stale Fuel Sheered Flywheel Key Bad Ignition Coil Incorrect Valve Clearances |

| Air Filter Clogged Jets Clogged or O-Rings in Carburetor Compromised Stale Fuel Bad Ignition Coil(s) Bad Spark Plug (2 Cylinder Engines) Incorrect Valve Clearances Sheered Flywheel Key |

What Causes “Backfire” or “Popping” in Lawn Mowers

To sum it up, the popping noise you are hearing is due to a problem with the combustion process in your engine. Things are either happening in too large of a quantity, too little of a quantity, too early, or too late.

If you have an engine that is running lean (more air than needed compared to fuel), then the combustion process is delayed due to the lack of fuel during compression. The combustion process happens, but not all within the time frame of when it should. It continues into the piston’s exhaust phase and pushes still-combusting fuel and air into the exhaust (mainly) and sometimes even back through the carburetor.

The sound was supposed to have been muffled within the chamber, but the bang from the combustion is now still occurring when the valves are open and now it can clearly be heard as a loud pop or bang.

A lean mixture can be commonly caused by stale fuel (fuel doesn’t combust fast enough), by clogged jets and emulsion tube in your carburetor, by a loose fitting carburetor (the nuts holding it on, a missing or damaged gasket), or a clogged fuel filter or screen.

If you have an engine that is running rich (more fuel than the needed air to combust it), then the combustion process is still delayed and the result is usually even louder bangs than with a lean engine. A rich mixture may combust on time, but in order to combust completely, the fuel needs the proper ratio of air. If the air is not present, then some of the fuel will fail to combust.

During the exhaust phase, the piston presses the mixture out into — you named it — the exhaust, and the fuel that didn’t combust now finds itself with air in the exhaust manifold and the temperature is high enough to spontaneously combust. This spontaneous combustion can be very loud.

A rich mixture is often caused by a clogged air filter, a stuck choke valve, or during rapid deceleration (you just mowed 9″ of thick, wet grass and transitioned immediately onto pavement).

The rich and lean mixtures are far easier to fix than the early or delayed combustion.

Early or delayed combustion can be caused by a sheered flywheel key, a malfunctioning ignition coil, or a dying spark plug. Other contributing factors can include valves that are stuck open when they should be closed, or incorrect valve lashes (the distance between the rocker arms and your valves).

If you hit a rock with the blades or a large stick or stump and your push mower has been popping ever since, there’s a good chance that you sheared the flywheel key and the timing is now off.

With the exception of switching out the spark plug, the rest of these possible problems involves some actual mechanical work to diagnose and repair. It can certainly be done if you’re willing to learn and invest in some tools, but I highly recommend addressing the lean and rich mixture problems first before chasing your tail with early or delayed combustion.

Why is My Push Mower Backfiring (Popping) and How to Fix

During use, push mowers will generally make a popping sound or backfire when they decelerate engine speed when going from thick or wet grass to thin grass. This is normal. However, if the backfire is continuous it could be due to stale fuel, clogged carburetor jets, a dirty air filter, or valve and timing issues.

If you are experiencing backfire or popping, it is best practice to first check the air filter to make sure it is not excessively dirty or wet from gasoline or oil.

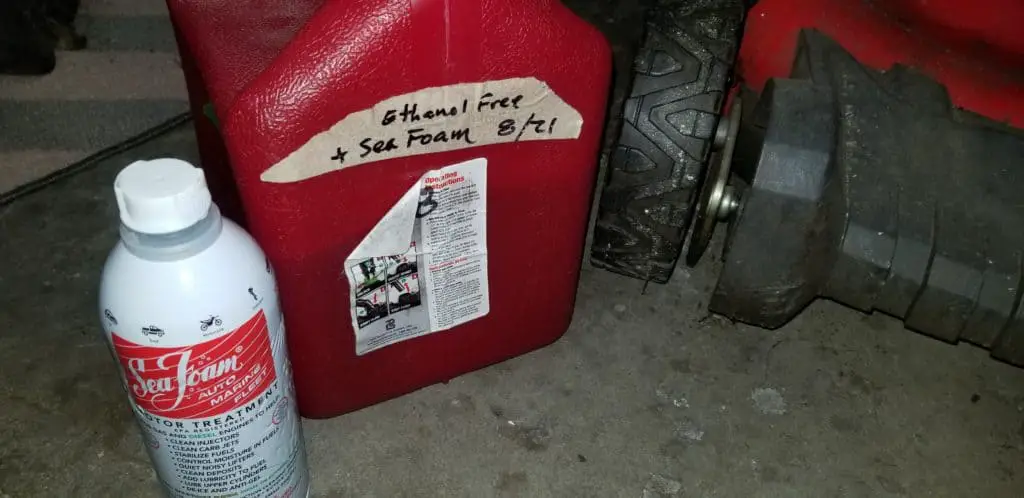

If this is fine, ask yourself how old the fuel is that you’re using. If the fuel is more than 3 months old and you did NOT treat it with a fuel stabilizer, then it is time to drain your tank and refill with fresh fuel.

To keep your fuel from going bad for up to 2 years (yes, I’ve tested it), I highly recommend using SeaFoam fuel stabilizer. Just add 1 fluid ounce per gallon of gas in your gas can, shake, and you’re ready to rock and roll for 2 years.

After checking the air filter and verifying that your fuel is good, you can then worry about removing and cleaning your carburetor. As you’re going to remove the carburetor, make sure that it isn’t loose to begin with. If the nuts or bolts aren’t tight, then you likely have a vacuum leak and the engine is sucking in more air than needed which will result in delayed combustion.

With the carburetor removed, you’ll want to clean out the pilot jet, the main jet, and the emulsion tube (if you have a simple carburetor with a metal bowl on the bottom). Make sure that the gaskets on either end of the carburetor are intact and present. A missing or torn gasket can also cause a vacuum leak and lead to popping sounds.

If you have a carburetor that looks like the one below, you’ll need to clean it by following the steps in the following video.

If you’re still experiencing popping or backfire, make sure to replace any fuel filters or screens that are present in the fuel line. There is also likely a screen inside the fuel tank itself that can get gummed up with varnish from stale fuel even though it might appear perfectly clean.

If you can’t easily blow through it, then it needs to be replaced. A clogged fuel filter (not common on push mowers) or a clogged screen in the tank can lead to the engine running lean since enough fuel can’t make it to the carburetor fast enough for the work being done.

Why is My Lawn Tractor (Riding Mower) Backfiring (Popping) and How to Fix

Normal popping or backfiring can occur for the same reason as mentioned above with the push mower.

If you are tackling thick or wet grass and you immediately transition to pavement or something thin, then in the brief moment where the engine was consuming a lot of fuel to not needing as much you can hear a popping sound. This happens since there is a momentary excess of fuel that isn’t needed and it experiences a delayed combustion for the new engine speed.

Engaging and disengaging your blades can also cause popping sounds for a moment and this is normal.

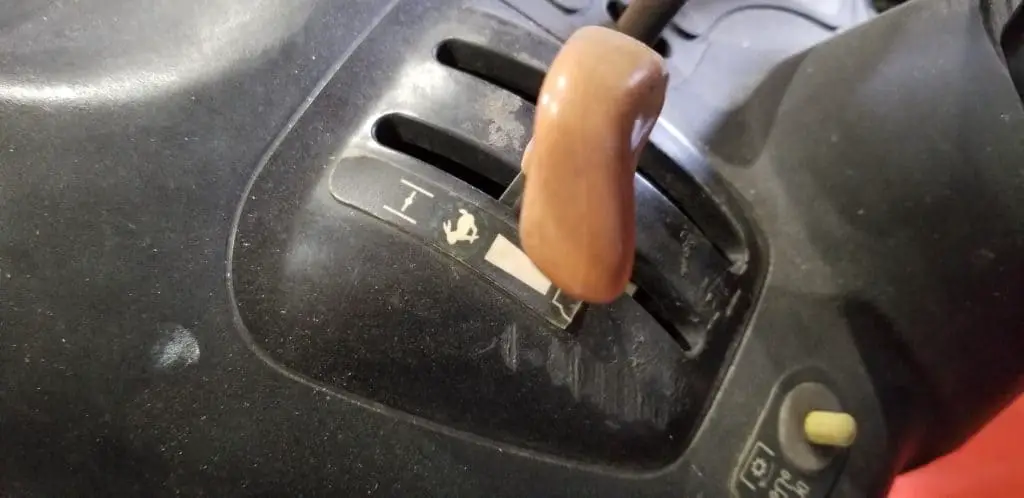

Moving your throttle from open to closed too quickly can also cause popping or backfire.

Any of these transitional moments where the engine goes from heavy work to less work too fast will lead to delayed combustion and an audible popping sound.

If the popping sound continues beyond these brief moments and is a constant thing, then we’ll need to do a few basic things before we outsource any mechanical work.

First, make sure that your fuel being used is not stale. Like I mentioned above, stale fuel can lead to delayed combustion which will create pops and bangs in your exhaust. Drain it or pump it out and fill with fresh fuel that has been treated with SeaFoam so that your gas will be good for up to 2 years.

After that, make sure that the inline fuel filter is not clogged. You should be able to blow easily through it when it’s disconnected. Make sure to shut off the fuel valve before you remove it. Replace if you meet a lot of resistance when blowing through it.

Also, go ahead and check your air filter to make sure the engine isn’t running too rich which can lead to popping sounds.

If the fix goes beyond that, the likely problem (from my experience) lies under your valve cover with the clearances of the valves or with any rubber o-rings inside of the carburetor that have deformed.

I haven’t had it happen to any of the riders that I’ve repaired, but I know that a failing ignition coil can cause popping and backfiring. You’ll need a tester to confirm that it is bad.

Your specific carburetor and valve adjustments are going to be different from each make and model, so it’s a bit difficult to explain here.

If you are able to access your valves to check the clearances, the exhaust valve is typically 0.005-0.007″ and the intake is 0.004-0.006″ with the feeler gauges. If there’s a lot of slop, then you will definitely hear some sputtering and popping. Typically the exhaust gets loose instead of the intake.

Some carburetors have lots of o-rings inside, and over time and with ethanol blended fuel, you are going to see them deform and stretch. Once this happens, the must be replaced in order to get proper combustion in your engine.

Look up your make and model for a carburetor rebuild kit (or just buy a new one) and for instructions on how to access yours.